I do have a small CNC project in mind (a drag knife cutter for foamboard, for RC airplanes) but there’s no rush at all.

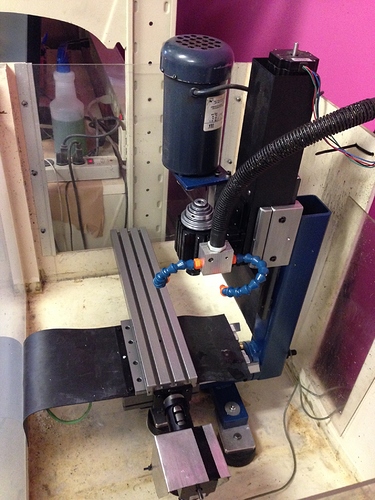

First stage of the upgrades are now complete. The machine is much faster and more accurate now. Wear and tear on screw life should be greatly decreased. With the original motors conservatively set the rapids on individual axis are around 60ipm, instead of 16ipm. Please be aware of the increased speed and increased chance for damage from collisions. Slow down the machine rapids when proving programs. The machine will be able to use smaller tools at higher RPMs much more effectively, I recommend ramping up your chip per tooth settings to match the new capabilities.

As always please oil the machine liberally before use to extend the life of the new screws and linear bearings. New coolant is on the way, the old stuff is very oily.

Stage two of the upgrades will be in place and I am working on making a new controller box. But completion for that is a significant amount of time away.

@Lukeo

@Jarrett

@rsim

@KevMacD

@lukecyca

@JayTheDude

@wander

@xquared

@Majicj

@workless

@hectorh

@Bobster747

@Emerson

@mike

@iMakeRobots

@Hekseskudd

@stchhx

@JDMc

@Rebel_without_Clause

@Logan_Buchy

piiiiiiiiics…!

Reminder please drive the machine home with G28 after using the machine turn off and disconnect the controller and switch off the computer with the power supply. Home the machine as shown in the photos. Also watch the interference between the ballscrew and the vice!!!

So I’m at the point where I should get some training. I’m available any weekday, any time. Sooner is more useful than later.

I would like to get trained up as well!!

I’m very interested in getting trained too ![]()

Hi please sign me up for CNC training as well.

PSA to trained people.

The machine sustained some significant damage! The alignment on the column was massively out of what causing very poor performance. Some very concerning issues have cropped up in the Z axis screw that I will have to look into more. If you cause damage there is no culture of blame here but the damage must be repaired, not only so that others can enjoy the high quality of work the Taig is capable of, but so that your own training can be improved and this kind of damage prevented in the future!

On a side note the spindle is at the very end of its lifespan, it may fail very soon and will have to be replaced.

@Gear105 wow. how bad is it? put a note on it that it’s out of order? any financial impact for the repair?

I realigned the column so the machine is cutting flat again. But what ever caused the misalignment may have shortened the lifespan of both the spindle and Z axis. It must have been one hell of a hit because I have never done anything like that myself. It’s working good for now. A new spindle is around $150 USD, a great deal for the relatively good performance of a spindle that size. I can also swap new bearings into the old headstock so there is a spare. The Z axis is a little more concerning because it is tight in a spot of the screw rotation. It is working for now but I will have to look into repairing it.

is the new ball screw safe??? ![]()

Training Waiting List

@stopmotionerin

@ryanmaclean

@3bien

@Janet

@Arrgh

@packetbob

@RobertButterworth

@ludovices

@Stefan

@LaShop

@hughl87

@msearracanada

@erik

@imsofluffy

Is anyone available in the upcoming week either during the day or evening? Roughly 8 hours is required.

People with a practical project idea in mind are a priority so I can tailor the course to individuals need given the limited time.

Hey @Gear105 - would love training. Can be available between 2 pm until 10pm on Monday or Thursday this coming week. The project I have in mind is this, if possible although I do not have materials yet (I hope to use scrap wood from VHS).

Also - remind me of the cost of training.

Thanks!

Janet

Please add me to the list. I could do next Thursday at 3 (have a call 2:30-3), but likely all the other people in list above me should go first and you wouldn’t have to “dumb it down” as much. I have a small project, to make some metal rings to hold some lights to the overhead in my kitchen.

Can you add me for a refresher course for the CAM part?

I didn’t get a chance to do much CAM after doing the VHS training, had some opportunity to do the plain vanilla G Code machining.

Or I can be an observer during the training.

I am available during the week and evenings and can move my schedule.

Thanks,

RK

Available any evenings, is it possible to break up the training or is it 8hrs in a row?

Thanks for setting up!

Hey Brian, fantastic! i could do thrusday or friday. Still interested in working on the ball and socket armatures ![]() im more flexible the week of the 15th, thanks, Erin

im more flexible the week of the 15th, thanks, Erin