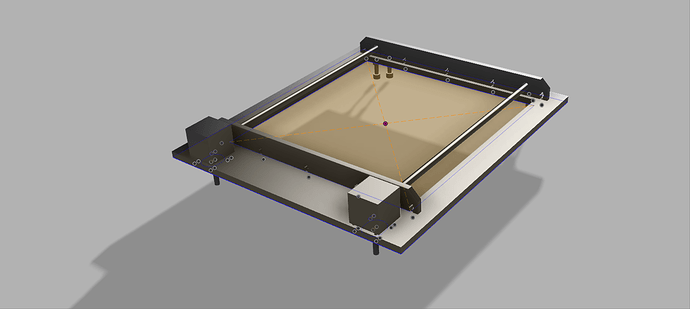

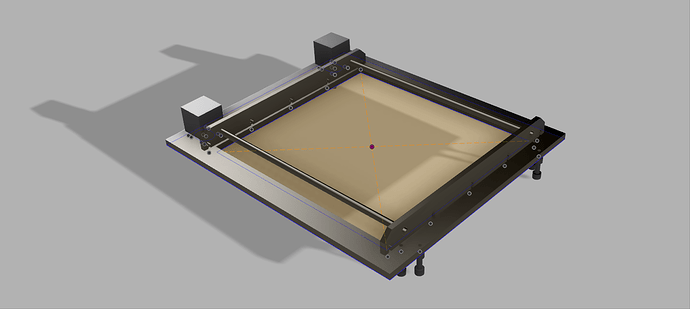

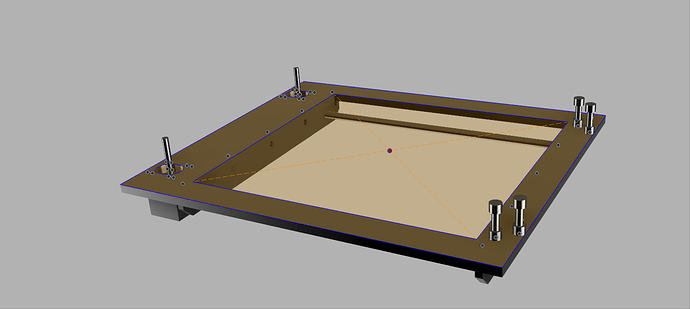

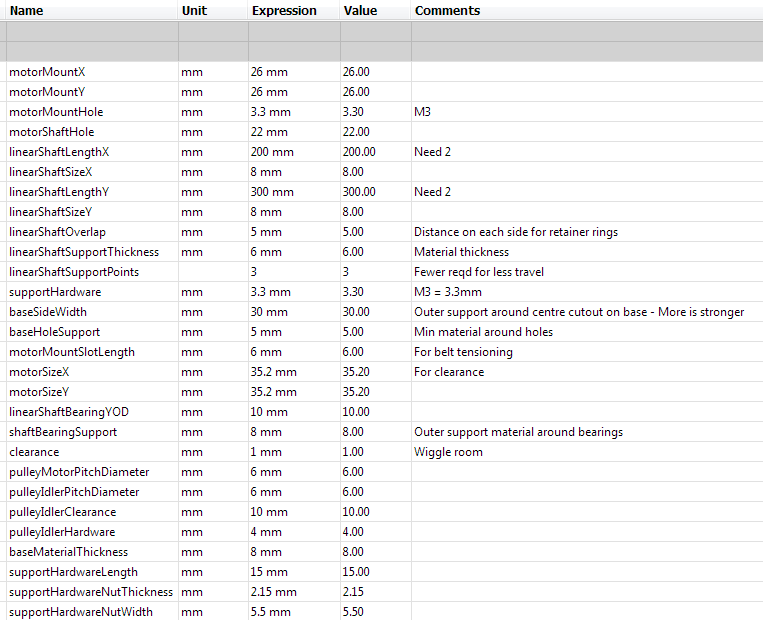

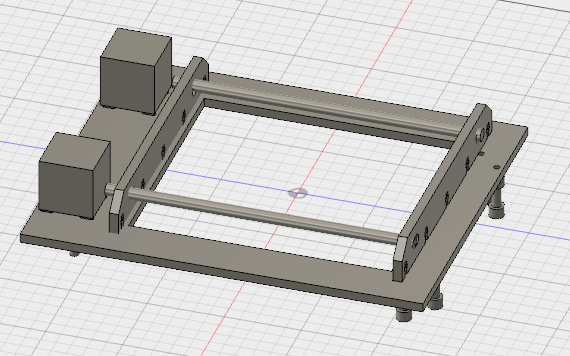

I am planning on making a small 30cm x 22cm (11" x 8.5") CoreXY CNC table using MakerBeam and a 500mW-2W laser diode.

Making it myself is NOT the cheapest or easiest or even the smartest solution. There are plenty of cheaper solutions that already exist and are available for sale on aliexpress/Kickstarter/Ebay/etc… There are also a huge selection of other DIY CNC cutters our there with full instructions and large communities built around them. If I just wanted all my problems to disappear, for a reasonable amount of money, I would just get a X-CARVE (from inventables) with a laser diode attachment. (X-CARVE is an amazing tool by the way, VHS should get one)

I want to learn more about CNC from the guts outwards. I want to know why people made the choices that made and I want to experience first hand the problems that exist. I am in no rush. I have most of the BoM already from other projects.

BoM

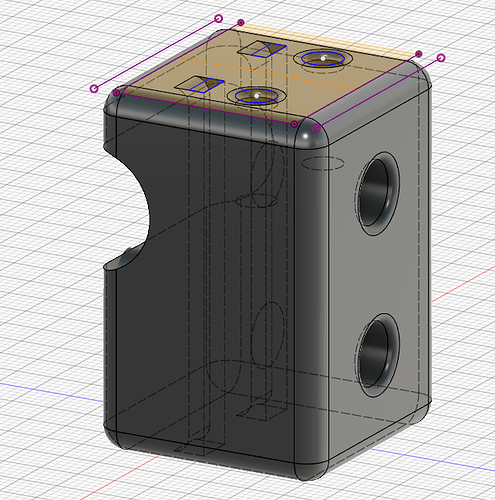

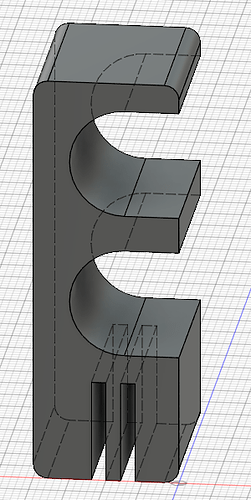

- $10 - 10pcs Idler Pulley Post

- $10 - 10pcs / pack bore 8mm GT2 20 teeth 6mm width timing pulley

- $10 - 2x 2pcs 20 teeth GT2 Pulley Bore 5mm + 2M GT2 timing Belt width 6mm

- $XX - 2x Nema 17 Stepper motors

- $XX - Maker Beam frame

- $XX - Arduino Uno

- $XX - Arduino Stepper Motor shield

- $XX - Raspberry PI

- $20-$140 - Laser diode (price depends on the power)

- $90 - Laser safety glasses

I decided to use the Maker Beam as the frame because I already has a full set of Maker Beam that I got from the creator when I visited him in SF at Maker Faire. Great guy. In exchange for delivering a few demo kits to a bunch of different hackspaces in a few other cities, that I was already going to, he gave me a full kit.

Software,

I am planning on using http://www.linuxcnc.org/, its open source, free, and is what many other projects seem to be using. It supports DFX and SVG.

The other option is to use just the Arduino running the motor shield that can intemperate GCode sent via serial USB. Again there are lots of examples of other projects that do this too. Then use a SVG or DFX to GCode converter. I don’t like this idea as much as I want the software stack to be as simple as possible.

Why:

VHS’s laser cutter shouldn’t be used for production projects. I have been making a bunch of laser cut paper craft for the last year. I have put some of the once off prototypes on Etsy.com. I would like to start doing production runs of some of the paper craft that I have been doing. I don’t want to abuse VHS’s laser cutter, and paying for $1 a min for laser time at Maker Labs +100 a month for membership, is too expensive for me. Since I live in a small apartment, I can’t store a full size laser cutter. They are also over kill for what I am doing. Instead I have decided to make a small portable one that I can use on my balcony.

Always open to suggests and feedback.