Another (short) night of Ukulele building tonight.

I picked up some woods for building my neck; but I wasn’t able to work on them tonight; I’ll have at that another day.

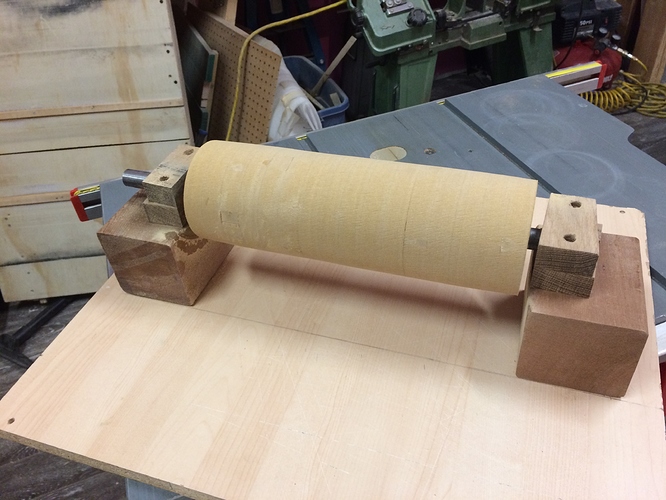

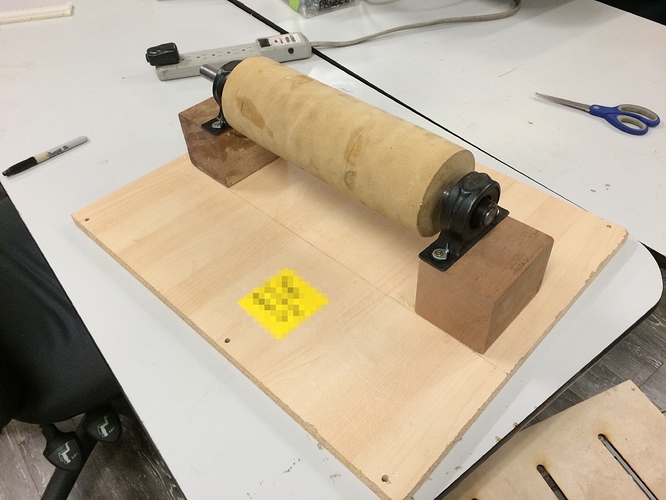

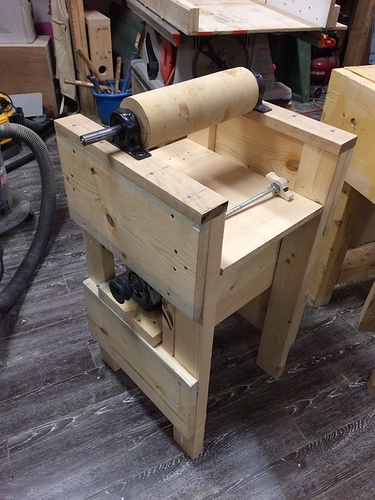

I also found a wire shelf being thrown away at my apartment; I grabbed one of the smaller ones right as the trash truck was pulling up. @TyIsI helped me bend one side to allow me to fit it into the ammo box, and with some wood spacers, we’ve now got a tray for wood steaming. This helps hold the wood, gives good access when we go to grab it (as it can slide out) and helps keep the wood in the hotter region of the steamer, allowing better efficiency.

I checked out my walnut side, after removing it from the form, and it turns out I put my good side on the inside. I’ll try sanding that one out; but there are some divots I made when trying to plane it down that I’m not proud of. If I can’t sand most of it out then I’ll probably end up having to cut another side.

I put my 2nd side in the steamer box and was about to start it up when one member complained that last time the steam made her ‘sick for days’. As a safety conscious person, I happily yielded to the request and offered not to steam that night. At which point, @TyIsI suggested I do my steaming in the loading dock. I set up everything there and had a successful steam. I don’t think I ever got the other member’s name, but I’m sorry that you feel I caused you harm.

While I disagree that the steam likely caused anyone to be sick, I recognize that I don’t know everything, there are too many unknowns, and that any safety concern should be met with the halting of the offending behavior. Removing my apparatus from the vicinity of the affected party seemed like a reasonable way to proceed.

If the safety committee still operates, I’d be happy to talk offline about how I can mitigate discomfort in the future, and what the ramifications of a steam bending night would be.

Here’s a pic of the new rack in the steamer:

http://imgur.com/9hY5rXG

( I actually ended up flipping the rack around before steaming it so the wood could sit even higher in the box ).

Hopefully I can start building the neck soon; I haven’t yet picked my soundboard (top piece of the body). Windsor plywood had nothing in-stock that would be suitable.

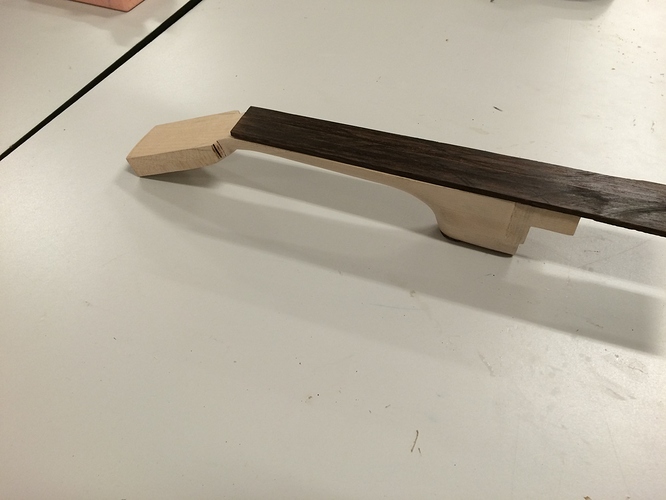

I’m looking forward to having something that at least starts looking like an instrument.