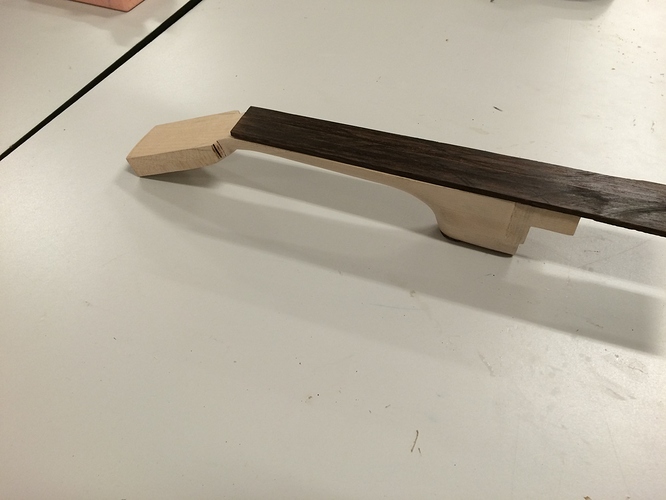

So I continue to shape and sand, the neck is just about the feel that I want. No use in posting a pic because its basically the same visually as the last state.

More interestingly; I’ve decided that I need to build yet another tool to complete this project ( I really didn’t but it will certainly make it easier, especially if I make more than one ).

A thickness sander is similar thickness planer, but instead of spinning blades, you have a spinning sanding spindle. This will be useful for getting various pieces down to very small thicknesses, such as the top and bottom, and my fretboard.

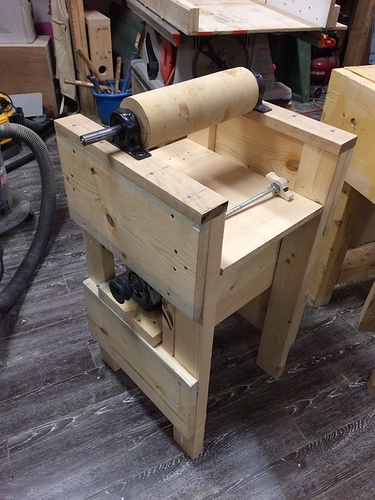

So this post details the work I’ve done so far on the thickness sander.

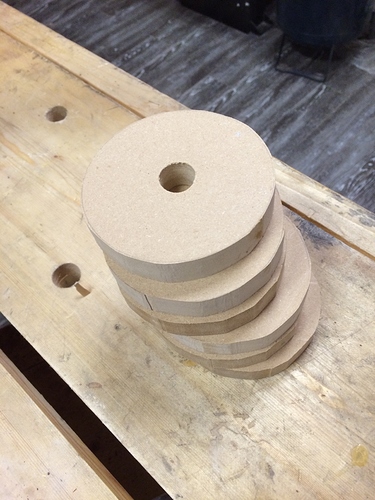

I bought a sheet of MDF, the thickest I could find, which was 3/4"

I lasercut some scrap baltic birch for some templates and then cut out a bunch of circles, first roughing them out with a jig saw then cleaning them up on the bandsaw, though they were intentionally left pretty rough.

Then I took a forstner bit and marked the center from the center punchout of the template (forstner bits have a little peak in the center to guide them). I used that mark to drill a pilot hole in each then used the same forstner bit to drill out a circle that matched the thickness of a metal shaft I’m using.

(Those are actually some of the nicer ones)

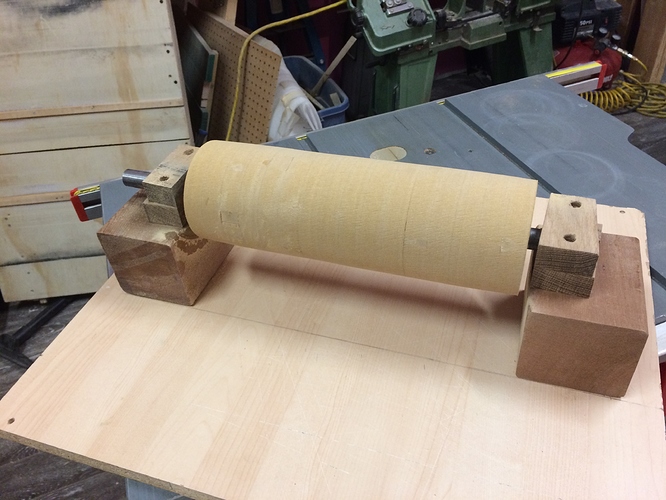

I glued sections of 5 together around the shaft. Being sure to move the shaft during drying in case leakage toward the center. I had a few close calls where I was only able to get it out with a mallet, but the dried came off easily with some high grit sandpaper.

After I had a group of 5, 5, and 6, I put them on the shaft and glued them together. They kinda remind me of shawarma…

While that dried, I cut some oak blocks and screwed two together. I took the 3/4" forstner bit (yes, that one bit is getting a lot of play on this project) and drilled sideways so that the hole was half on each block. I did that twice for two wooden bearings. I mounted them on a couple blocks of wood screwed to a board.

I took the whole thing at a 45 degree angle onto the belt sander and sanded down most of the irregularities.

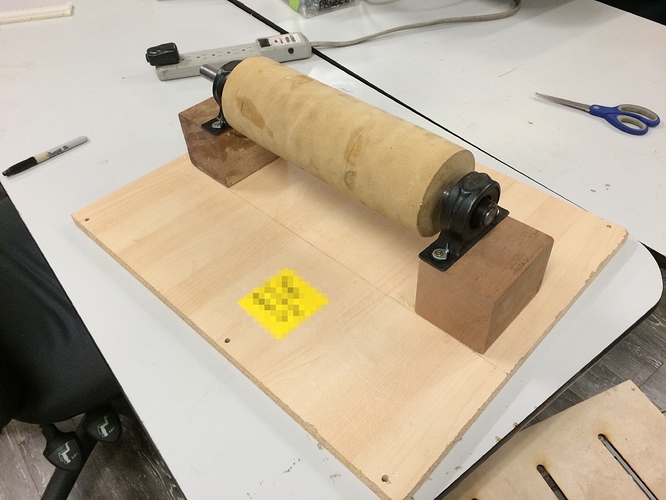

After finding some pillow blocks and mounting them temporarily, I called it a night.

Next I’ll need to build the table for this to mount to and figure out the drive mechanics.