There’s a couple set screws that are accessible from the top of the table saw. I cleaned up the stop bracket on the grinder and then retracted the set screw almost all the way until it was square. I think I got it within a fraction degree of square (as close as i’m able to measure).

There’s also a second screw that I think is for the 45 degree set, but I am having a little more trouble setting that one. (Sorry I did not take a photo of the set screw)

As far as the stiffness, there was some grime (mostly compressed sawdust) on the threaded shaft. I brushed those off nice and clean and then added some lubricant. There was actually quite a bit of material stuck in odd places; I ended up tipping it over 4-5 times and each time I found a new set of dust in weird places. There’s also a removable, clipped cover for the saw cavity, which yielded some stuck pieces of wood that couldn’t be expelled out the dust collection port.

I also noticed some adjustment bars for the fence rails were loose on the ‘off’ side, I didn’t adjust those since you had gotten the right-side square, but those might be able to be brought close to true; though I suspect those rails are indeed bent, so I left it alone for now.

I also scraped off some of the glue from the table top. Unfortunately that was probably my doing, I don’t think I realized I had a few drips a couple weeks back; I thought I cleaned it all up. I needed a flat surface, and unfortunately the table saw is the flattest surface we’ve got.

Of note, when I put the sled on the table, it had to cut through a tiny bit of material on the back because the blade apparently wasn’t square when that was built; I suspect the set screw has been wrong since we obtained the saw. If the angle indicator can be adjusted; it would be nice to true that up, at least as a rough indication of your angle.

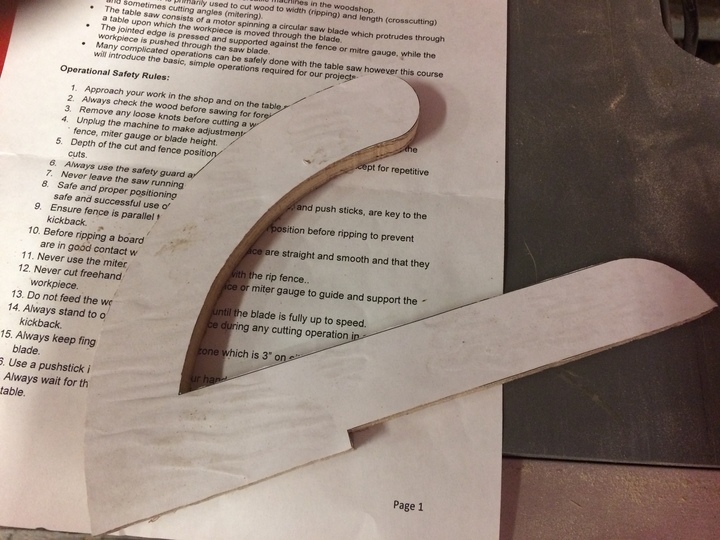

Also, per the class, our push sticks were of the wrong material and style. I’ve gone ahead and made one with @Stevemopolis’s template, but with the lip reduced for smaller material.

Pictured below with one of the handouts from the class.

Also, do we have an angle gauge that I can use to validate the 45 degree set is correct?

I certainly think we should be purchasing a new table saw; but with at least the major couple problems out of the way; maybe we can figure out a way to fundraise to a saw that is excellent rather than just an improvement?

Personally I think we should aim to check off all of the ‘things to look for’ as well as the ‘desirable not not completely necessary’.

I believe I’ve just sold the large lathe, which I was going to donate to VHS, but I don’t think its worth us keeping it given how much better the mini lathe is (and not worth the space). That money ($50) is earmarked for my donation to an equipment purchase such as a table saw.