Super fun night tonight! Had a great time. Thanks to all the people who ordered parts!

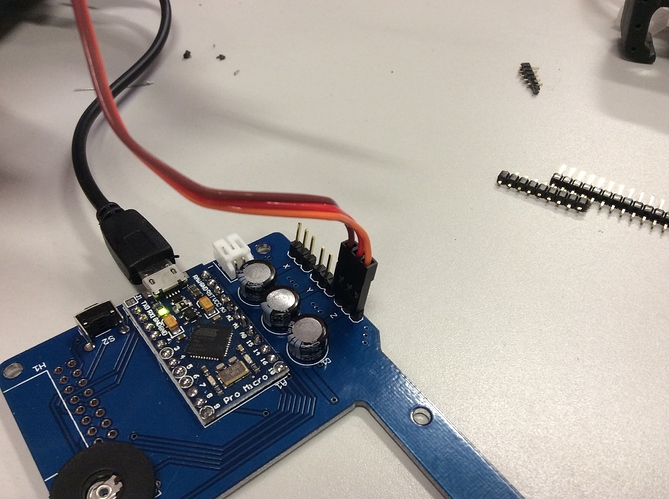

I agree, it was great to finally meet people in their corporeal instantiation ![]() . I updated the spreadsheet to keep track of where we’re at with parts. I’m not exactly sure who got a pcb so maybe @TomKeddie you can check if I got it right. At the moment I have 7 pcb’s and 6 parts kits from Tom - @jon has the servo’s and thumbwheels.

. I updated the spreadsheet to keep track of where we’re at with parts. I’m not exactly sure who got a pcb so maybe @TomKeddie you can check if I got it right. At the moment I have 7 pcb’s and 6 parts kits from Tom - @jon has the servo’s and thumbwheels.

I’ll be at VHS on both Tue and Thur from around 7:15 until 8:45 either day so hopefully we can get the kits distributed next week.

Huge success on the build night. Thanks for Randy, Tom, John, Ignacio, and

everyone else who helped get parts and organize the event!

@TomKeddie - What was the socket used for the power (JST) ? I’ll pop past Lees and pick up a few as I can see that I’ll need to build a separate power supply for this to properly power the servos (rather than depend on the USB source)

Yep according to the parts list it is a jst (Piccolo Bill of Materials · DiatomStudio/Piccolo Wiki · GitHub), I have some at home I realise now, should have tested them.

Lees should have them with wire tails, they’re use a lot on LiIon batteries.

Hi all,

I’d like to get the Piccolo build restarted.

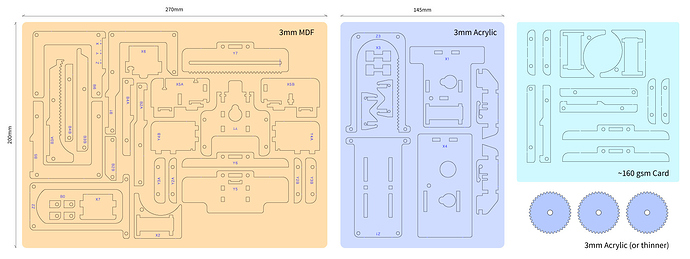

We need to get acrylic and MDF board cut on a laser to finish things.

Here’s a link to the build instructions: Piccolo Fabrication Guide · DiatomStudio/Piccolo Wiki · GitHub

Each person’s MDF piece is 20 cm by 27 cm, and the acrylic is 20 cm by 14.5 cm, plus the three gears. There’s also GSM card used for spacing if the acrylic is thicker or the same thickness as the MDF.

I haven’t had any laser layout or cutting experience, but I’m willing to get materials if someone knows a source.

Since we can’t cut MDF on our own laser anyway, perhaps we should hit MakerLabs?

Let’s bring these machines to life!

Alright - thanks Andrew!

Should we take a poll of who needs mdf/acrylic cut, and also the nuts/bolts? I added a couple of columns to the parts spreadsheet - if people could indicate whether they need the materials, we can get an idea of how much we need to buy/cut as a group.

I’ve sort of been looking around for a source for the acrylic - any recommendation as to suppliers? Also any comment about spec’s for it - there seem to be a number of different things that are listed as “acrylic”. For example, I came across an offcut for cheap, but it didn’t have the paper protection anymore - is this a requirement for laser cutting?

Suppliers here:

http://vanhack.ca/doku.php?id=suppliers

The only thing we care about is that it is the proper thickness of acrylic. There are a bunch of different brands and qualities, but it doesn’t really matter. Paper protection is not important.

Offcuts are better because they are (substantially) cheaper, but they come in weird sizes, and may end up being more difficult to laser because of that.

Not that it helps with a non-operational laser, but for future builds is there any reason the MDF couldn’t be Birch ply? I understand that it can’t be acrylic because it needs to slide well against acrylic, and acrylic on acrylic is higher friction.

I saw some acrylic sheets at Dumbar lumber, I was browsing their plywood

selection in anticipation for the big day when the laser cutter reopens. I

was asking about prices of various sheets, when I asked about acrylic I got

a stern look and was just told that it was “very expensive”.

A couple of weeks ago I saw a piece of 3mm acrylic at Windsor (near Granville St) that was about 30" x 60" . It was marked $30 but before the guy saw the price he asked me how much I wanted to pay. They don’t normally carry that type of material, so they really just wanted to get rid of it. In fact they had a number of decent size partial sheets of various sizes of plastic, acrylic etc. for anyone looking for bargains.

It wasn’t well covered but had only a few cosmetic scratches. I can check Sat am and see if it’s still there … It was marked 3mm, so it may be good for the gears anyway since 1/8" is slightly bigger than 3mm.

OK, I bought the acrylic half-sheet. It’s 65 x 157 cm, which is enough for 28 squares, more than enough. It is spec’ed as 3mm (.118 in) so it might be tricky with the gears since they need to be a bit shallower.

No worries if we don’t use it - I can keep it for other projects. Or maybe we can use this for the gears, if there’s a better alternative for the main parts.

Wow, thanks for doing this!

Alright, I bought two sheets of 3mm MDF, 2" x 4". I think that’s enough for

everyone (somebody check my math, it was a strange day.)

I checked it with calipers, it’s ~3.15 mm.

It’s in the laser materials storage area, marked with green painter’s tape.

Next steps: laser cut a prototype at Maker Labs? Who is a member there?

[quote=“Andrew_Hendriks, post:193, topic:825”]

Alright, I bought two sheets of 3mm MDF, 2" x 4". … It’s in the laser materials storage area, marked with green painter’s tape.

[/quote]I put the acrylic sheet beside the MDF in the storage area. It looks like the dimensions of the material we have is opposite what they used - their cutting pattern is based on the acrylic being slightly thicker. They offer some ideas on adjusting the pattern.

I think some people have already cut some materials on their own ( @johnbiehler ? ) - has anyone assembled this yet and have some words of wisdom? How critical is having gears thinner than the acrylic, can the paper spacers accommodate all these various issues?

Recording this list here.

Update on the chassis/gears:

The Laser Cutter Committee has been working very hard to get the laser

cutter online.

We should be able to get some test cuts of the acrylic soon (a few days?)

so we can see how well it fits together and runs.

Thanks go to @rsim, @jon, @garthomite, and everyone else involved in

getting the laser operational.

Thanks for moving this forward. Can you let me know when you’re going to do this? I know next to nothing about modifying the image file and printing it on the laser cutter and I’d like to observe the process (if you’re lucky, I may even be helpful!)

The proper laser cutter files have already been prepared, and are in my folder on the laser cutter computer.

If you want to learn more, though, I hear @funvill has a workshop coming up ![]()