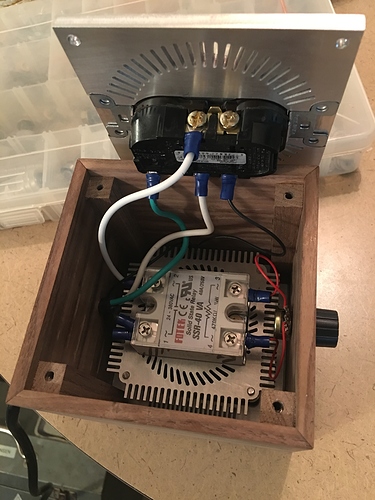

I’ve done a bunch of experimenting with high-current SSRs over the last couple years, controlled by microcontrollers as well as cheap “PID controllers”. Here’s a bit of an overview of my experiences.

Firstly, this document is a great overview of the quirks and limitations of using SSRs.

PWM

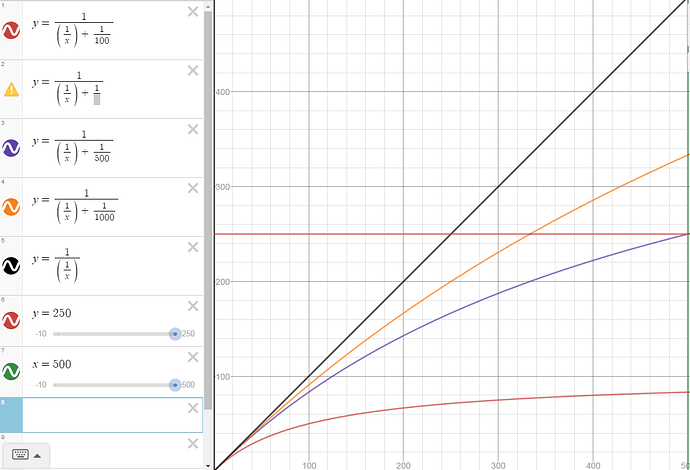

Usually when people refer to PWM, it’s for high-frequency DC switching, such as dimming LEDs from an Arduino. A Solid-state relay can take a PWM signal and sort of apply it to AC, but the results won’t be very good because most SSRs only trigger on a zero-crossing of the AC waveform. If the PWM frequency is quite fast (as it usually is) then the results will be quite unpredictable.

A better way to “dim” AC power is to use phase control. This is a similar principal to regular DC PWM, but synchronizes the switching to the AC frequency for more predictable and linear results. Essentially it just hacks off part of the AC waveform to get a lower average power.

http://ecmweb.com/site-files/ecmweb.com/files/uploads/2015/01/Leading-Edge.jpg

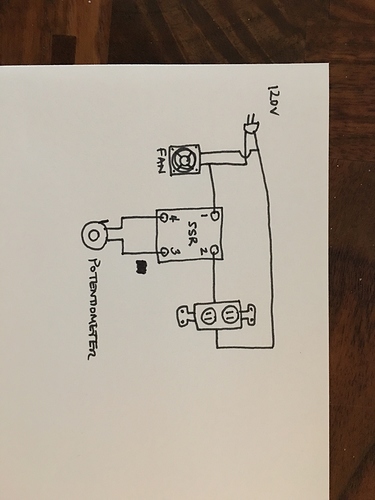

From the datasheet for your SSR-40 VA4, it appears it does indeed do phase control switching based on the resistance of the attached potentiometer. So that’s good.

PID

http://sion.rs/image/cache/data/REX-C100%20800x800-500x500.jpg

PID is just a general control algorithm and can be applied to many different things. In the context of heating a tank of liquid, a “PID Controller” usually refers to a device like the REX C-100 above. You connect a thermocouple and give it a set point temperature. It performs a PID algorithm and pulses a DC current at an appropriate duty cycle so that you can drive a regular zero-crossing SSR to switch a big AC heating element. Crucially, it operates at very low frequency (several seconds), so the SSR’s zero-crossing switching characteristic doesn’t really matter.

In the end, I guess it is still doing PWM, but at a frequency that is much much lower than the 60Hz AC waveform.

Since you’re heating a large thermal mass, you can afford to have such a slow switching frequency. Whereas if you were dimming LEDs, you’d need a very high switching frequency in order for the human eye to perceive it as a dim light.

BTW, I have a spare REX C100 that I’m happy to part with if anyone has an immediate use for it.