when last we left our intrepid heroes…

I’ve started to settle in in Toronto, and found the necessities of life - lodging, power, internet, and, tentatively, a maker space. It is a truth universally acknowledged, that a maker in possession of a good makerspace membership, must be in want of a project to try out their resources. I’ve got a few things on my projects list (don’t we all?), but for all the reasons that the pinball table fascinated me in the first place, it’s drawing me back.

They don’t seem to have much of a web forum presence, so I figured I’d keep using talk until I get around to setting up a blog.

First question - why start over, rather than continue the previous project?

Primarily, I ended up feeling that the multiplayer pinball concept created a lot of challenges that were less interesting, and entirely additional to, the inherent difficulties of a custom pinball project.

- The ball feed mechanism was going to be a giant hairy mess - we’d be essentially building most of a fairly complicated Rolling Ball Sculpture to feed balls onto the table. From my research, these are both notoriously finicky, and unreliable.

- Frame / support - a traditional pinball cabinet is quite simple, basically a box with a slanted top, due to the large size and separate panelized nature of the multiplayer design, this was going to require some clever design, and a fair bit of work to fabricate.

- scoring/game logic. There’s a surprising amount of resources for custom pinball software - the Mission Pinball Framework is an opensource framework that saves a lot of time on the common game management logic of a traditional pinball machine, but it wouldn’t have been feasible to adapt it to the multiplayer design.

- scale and transportability - the multiple panels caused a large physical size, which was difficult to pull out/put away as it was worked on.

- cost - having to buy 3 sets of everything drove the projected costs of the project sky high.

- etc.

There’s lots of things with a traditional design that things have an “off the shelf” solution. That’s attractive in terms of actually delivering on a very large scope project.

A final aspect is that I ended up a bit disappointed with the constraints in how the machine felt to play. It was designed to get by on novelty, not provide a deep playing experience. The wide open layout contributed to this. This was an explicit choice I had originally thought was a clever way to reduce the pressure on the playfield design, but in the end I kind of regret it.

I may return to Tri-Orbital Terror, and it’s general design, but for now, I want to take a crack at a more traditional game.

Starting Over.

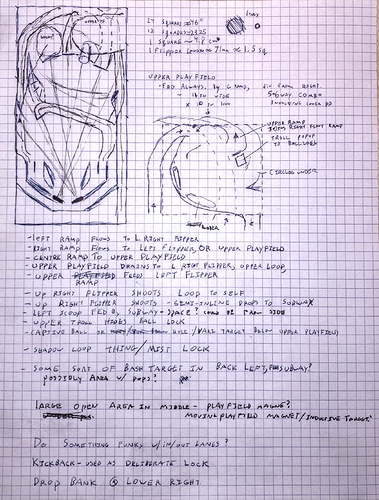

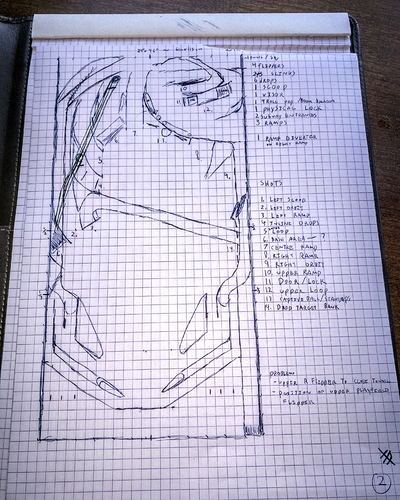

So, here’s some thoughts I started with to start sketching out a new design.

- Generally traditional size/layout.

- There’s two common sizes of pinball table, both are 45.00" long. “standard” width is 20.25", “widebody” or “superpin” size is 23.25".

- I’m currently planning widebody, as it gives more room for mechanisms under the playfield, etc. Building from scratch in quantity 1, the incremental costs of widebody appear pretty minimal.

- Game should “Flow” - shots should feed other shots, most shots should keep things moving. include Ramps.

- Shot based games - aim the ball, don’t just toss it into an area of the playfield.

- Theme will be a later decision, but plan on doing it as a fan-work, using an existing theme, rather than custom artwork (this approach seems really common for custom pinball machines.)

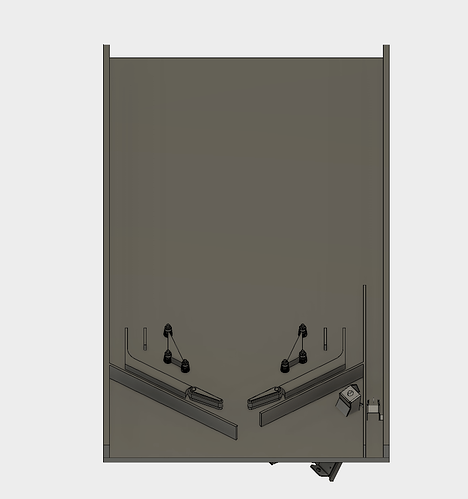

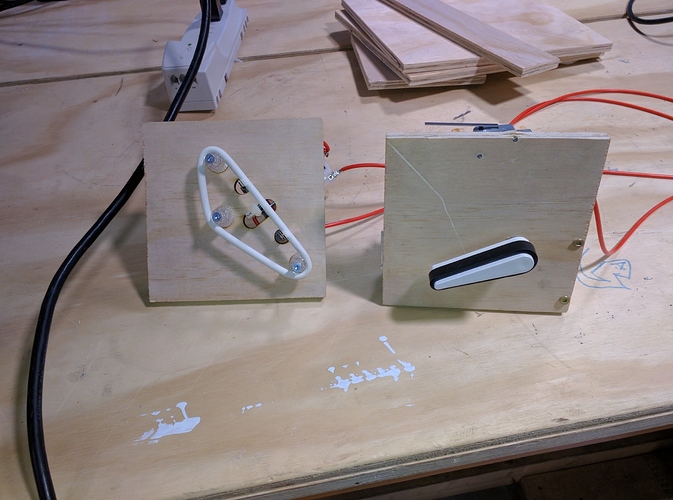

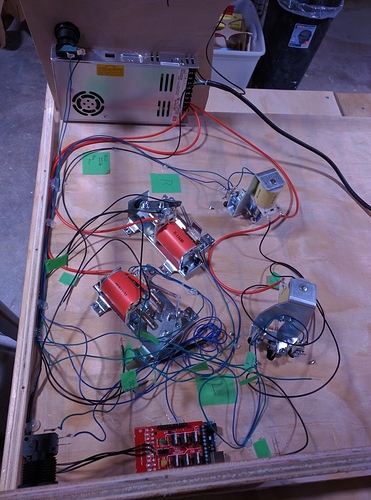

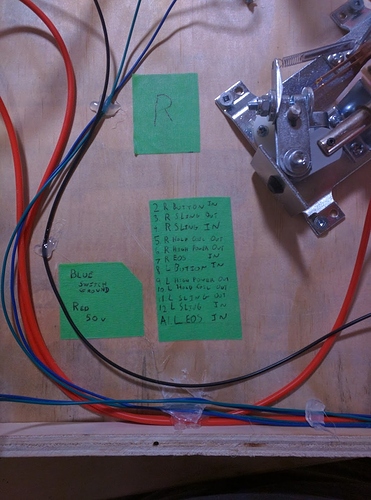

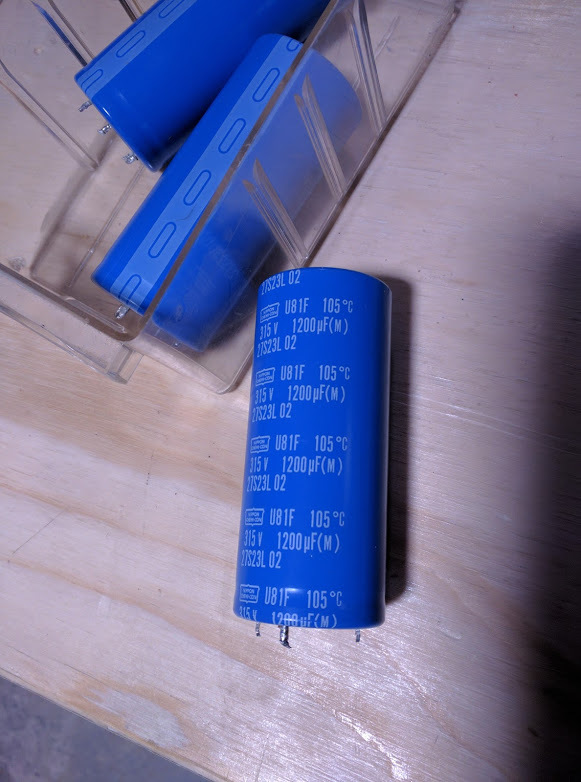

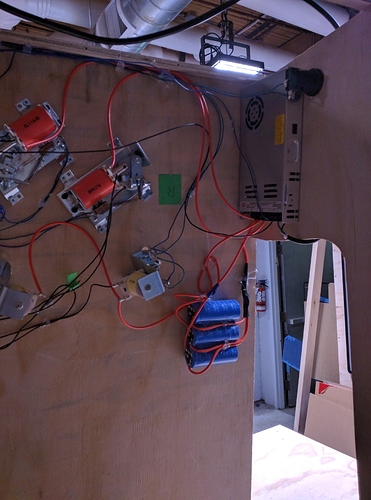

- Start with prototyping the shots and layout with just hardwired flippers, switches and a power supply - worry later about electronics, scoring and control.

- some half-assed ideas for mechanisms I wanted to use.