About a month ago, I had a sheet of 1/4" clear acrylic delivered to the space (Acrylic Sheet Group Buy)

Here’s what I built with it:

It’s a display case to enclose a meteorite that is normally touchable by visitors. For covid reasons, they want to avoid high-touch exhibits currently

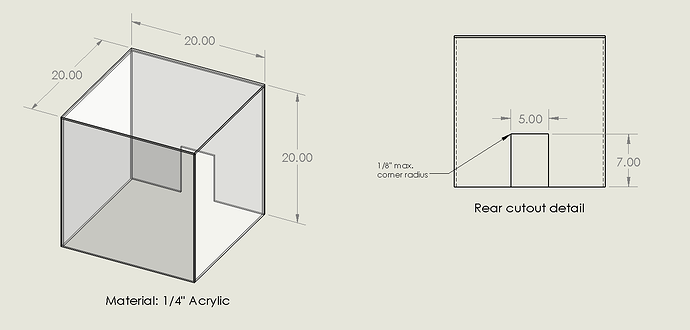

First I took some measurements of the exhibit, and then I designed the display case in Solidworks:

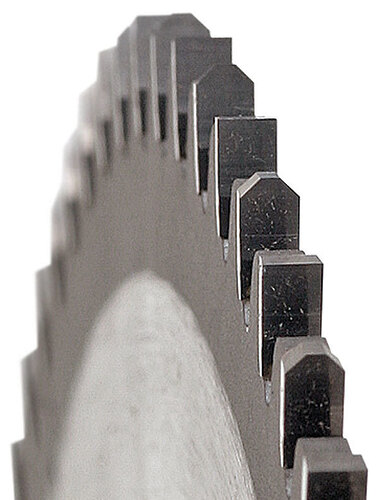

Then I cut the pieces on our shiny new table saw using a special sawblade for plastics (aka a Triple Chip blade), which cut the acrylic with a nice smooth edge finish. The rear piece has a rectangular cutout, which I laser-cut:

I solvent welded the pieces together with “Weldon 4” and a needle-tip squeeze bottle. The solvent is a very thin liquid that wicks itself into the seams.

Corner clamps help keep everything aligned while solvent welding:

I have donated these corner clamps to the space. They’re currently hanging on the pegboard in the woodshop.

I solvent welded the top piece on last, after the sides had all been welded together:

To facilitate solvent welding, the sides and top overhang each other slightly and I trimmed them flush with a flush trim router bit:

I removed the blue protective film and flame-polished the edges with a propane torch (I don’t have any photos of this process unfortunately)

Finally, I installed the display case at the H.R. MacMillan Space Centre this morning. I drilled a few small holes to attach the display case to the base of the stand with some small machine screws, and it’s finished!