You might want to look at the CRAMPS expansion board for the beaglebone. A group of us built these a few years back. Machinekit is a linuxcnc distro for the beaglebone.

Awesome, I will take a look there.

So I bought 9 of these…

HSS57 driver.pdf (271.1 KB)

nema23 DW57HSE2N-D25.pdf (105.1 KB)

One set of three is going on the Taig as is exists now running Mach 3 with a new parallel port breakout board, possibly this one… http://www.probotix.com/BREAKOUT-BOARDS/PBX-2-CNC-Parallel-Port-Breakout-Board

Second set of three is going to be run by the Beagle Bone Black with this cape maybe, http://www.probotix.com/BREAKOUT-BOARDS/PBX-BB-BeagleBone-Breakout-Board

Third set of three is going to be run by a PC possibly with the industrial version of Mach4

and either this motion controller on the high end Mach4 Motion Control Board, Mach4 CNC Ethernet Motion Controller - HiCON Integra

or this one Motion Controllers - Motion Control or this one on the low end http://www.pmdx.com/

@TomKeddie I will have to try out the CRAMPS with some nema17s in the future.

The header on this cape is a little disheartening.

Does anyone know what cape the PocketCNC is running?

It’s very light duty. I’m in the process of designing a simple cape (ie. just 3.3V->5V conversion and headers) to drive the motor drivers I brought back from China last month. The interface is a simple set of optocouplers.

https://item.taobao.com/item.htm?spm=a312a.7700846.0.0.EvARTW&id=527024123641&_u=g1sfp74r3209

Very similar to yours.

I guess not having tool path display is OK for the price difference… Did a preliminary part pick for a Mach 4 computer and the damage was around $300.

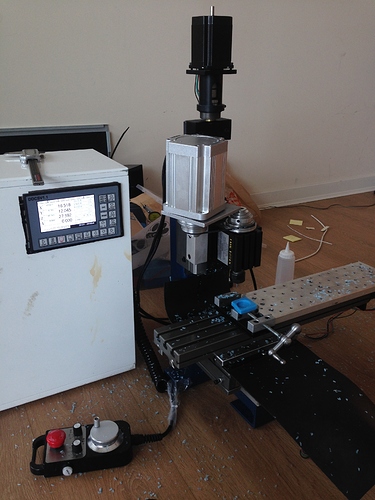

Turns out this thread was the motivation I needed to get everything up and running.

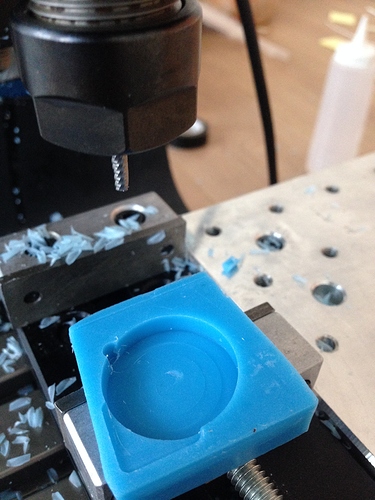

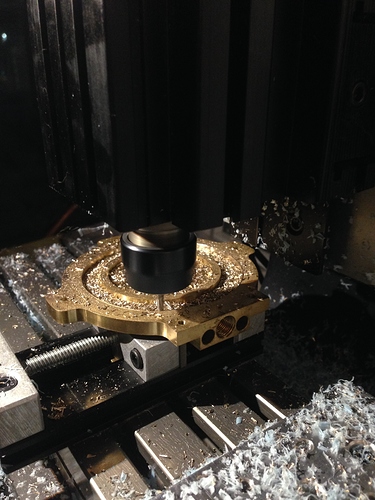

Had some configuration kinks to work out with the controller, but it works reasonably well and I enjoy having the MPG to zero the work. I opted for a brushless spindle motor (over the stock AC one) so that I can set RPM through gcode and not have to deal with adjusting the pulleys. I broke an end mill almost immediately - turns out the motor spins CCW by default…

Does anyone know a good place to buy offcuts of aluminum, and metal in general (preferably in the Vancouver area)? Looking to make some hold downs so I can mount my screwless vise.

Looks great.

Check out our local supplier page for metal shops:

Thanks - popped by Northstar today and picked up some aluminum. The staff and owner were all pretty friendly and helpful. Good place for larger pieces of 2-3 mm aluminum sheets, useful bar stock was a bit more scarce as most pieces in the aluminum bin were CNC offcuts in irregular shapes.

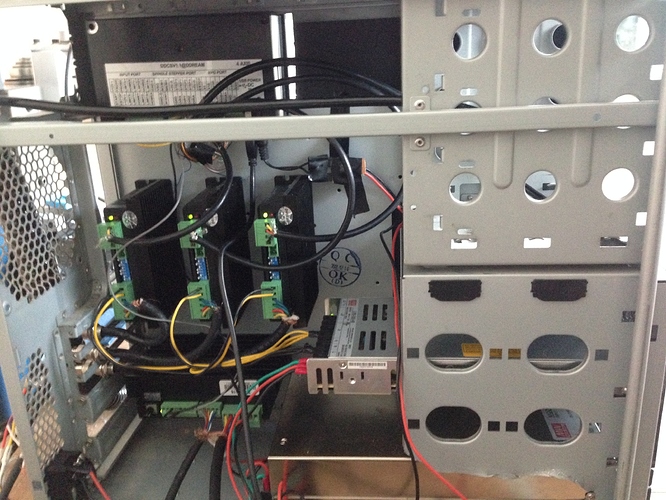

How much HP does that spindle motor have? How are you liking the controller? Its cool how you arranged the controller components in an old PC.

It’s 500W so around 0.67hp. Probably a bit oversized; I did some reading up (after making the purchase) which seemed to suggest that the bottleneck for smaller mills is frame stiffness. It also seems from plugging numbers into feed and speeds calculators that smaller OD endmills will deflect long before HP becomes the limiting factor. I like that there’s feedback so that the driver will try to maintain constant RPM even under load, though.

The controller is working great so far - everything pretty much works as you’d expect. The only major downside is that documentation is pretty barebones, and as it’s relatively new there isn’t much of a community for it. It looks like people have started hacking the firmware though, and they’ve begun working on open source firmware for it.:

I don’t have any experience with Mach3/4, but personally I think it’s a great alternative especially when cost is taken into account (it costs the same as a mach3 license). I like how much it simplifies the build in terms of not needing a separate PC, monitor, or an interface between the drivers and the PC (i.e. smoothstepper), and that everything can be a self contained enclosure.

Seems like a good deal for sure. Mach does have some nice options, but does add a lot of complexity that is for sure. You may find that spindle motor to be under powered. The machine may bend under heavier cuts but that doesn’t mean it can’t take them, it is fairly easy to stall out the 1-1/4 HP motor that is standard. Having a VFD is quite nice.

The stock (upgraded, CNC ready) motor is only 1/4hp actually (http://www.taigtools.com/mmill.html), which is why I figure I’d move up to something a bit beefier. Taig also charges $175 less for a mill without the motor, which made it a much easier decision.

I looked into a VFD + eBay spindle initially, but a brushless motor + driver ended up being much more cost effective (around $100) and supposedly the Taig spindles are pretty well regarded.

Oh yeah! That does make a lot more sense. I got that all wrong. The motor also looks lighter. The Taig spindles for the cost are very robust.

Hi Ryan

Do you have a link for the spindle motor and drive you used? I have an EMCO F1 chassis I’m trying to stick together and the motor looks about the size I’m after.

Thanks in advance,

Andrew Hutchinson

https://item.taobao.com/item.htm?spm=a312a.7700846.0.0.D8X9fc&id=22128856466&_u=62bv29q3c28a

https://item.taobao.com/item.htm?spm=a312a.7700846.0.0.D8X9fc&id=12545658761&_u=62bv29q36ea5

You’ll also need a 48V 500Wish power supply. (http://m.intl.taobao.com/detail/detail.html?spm=a1z09.2.0.0.5lyDJd&id=520213056634&_u=82bv29q3a76c is the one I got)

e: the ampersands in the links weren’t being parsed correctly

@Gear105 I saw that from your other thread and it looks promising, but a bit above my budget and it looks like it still needs a bit more polishing (Any User Input?? - Hind Technologies / Masso HTG5A1S Controller).

My current controller works fine for the most part, but isn’t ideal in the sense that I haven’t found a post processor for Fusion 360 that plays 100% nicely with it. A lot of problems were, in retrospect, problems with the posts themselves (they insert a G91.1 into the header to put the controller into incremental mode even though the gcode themselves is absolute, so my mill would rapid to nowhere), but it also seems to have occasional problems interpreting arcs. At least having to troubleshoot this forced me to learn gcode, so I’ve got that going for me, which is nice.

Have you looked into linuxcnc, and in particular the PathPilot variant? Of all the hobby level options it seems like PathPilot has the best interface (imo), and that it’s possible to get it to work on non-Tormachs. I probably have an unfair/ignorant bias against Mach 3/4 because the interface just looks pretty ill thought out.

@TomKeddie Taobao has an official/integrated consolidating shipping service that works decently well, charging around $19 CAD for the first KG and $4 CAD for every 0.5kg thereafter. It ships via DHL which itself only takes around 2 days (!!), but it takes them around a day or two to process each taobao order, and another 2-3 days to package it and get it to the DHL warehouse. I was surprised to find that DHL actually has really reasonable customs handling fees; it’s something like a max of $7 plus actual taxes/duties owed. That said, the shipping service has a tendency to misdeclare the shipment value and contents (even after I insisted that they declare the actual value, they declared a $200 order as $10 worth of “e cigarette parts” wtf), and I’m somewhat concerned that that’ll eventually get me in trouble with customs. The other downside is that Taobao tends to disallow orders of industrialish items (i.e. end mills) from being reshipped this way.

To get around that I now use http://www.jfchinese.com/Index/enindex.html, which gives you a local shipping address so that there are no restrictions on what you can order. They also process shipments much more quickly (same day to receive, and same day to ship), though their Hong Kong DHL options is only slightly more expensive than the official shipping consolidators.

Anyway, with reasonable and fast shipping, Taobao is an amazing resource for prototyping/hobby stuff. There are very few things that I haven’t been able to source in single/low quantities, and stuff usually arrive sooner than order things from the States.

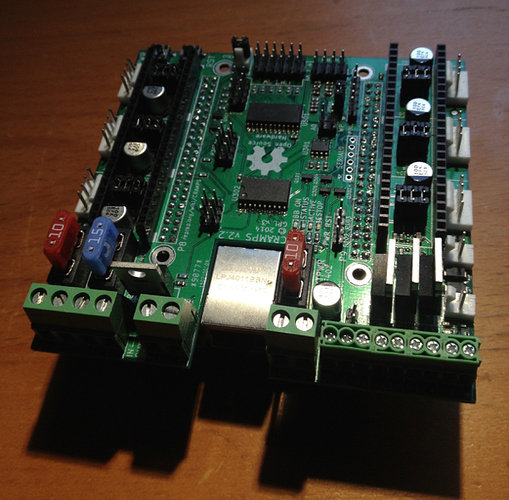

Bit late to the party but this is the CRAMPs/BBB controller that I built as part of the VHS group build.

I’ve tested it with stepper motors and LinuxCNC and seems to work ok.

Now I just need to build the rest of the CNC.

Seems like it’s time to start.

Mark

You can edit and customize post processors to suit your controller. Have you tried using the Fanuc one? It is a pretty common starting point. I use Path Pilot and Mach 3 regularly and I find them to be very similar in function and layout. I like and dislike things about both of them. The Masso seems like another good option and I would like to try it out. I have looked into the BBB and capes, I will try one out in the future.