As my current favourite project is primarily a software one, I really need something on the side to keep my hands busy.

So I opted to do a small, easy metal lathe project. You know how those go, right?

It’s been a handful of years since I’ve used a lathe with any regularity, so I was itching to get back into it.

It ended up taking over 40 hours, mostly because I am bad at this. But I learned a lot!

Initially, this was going to be all brass, but Metal Supermarket doesn’t really carry a lot of red metals. Metal Supermarket is awesome, but pretty much the only stuff they carry is solid brass rod. It’s difficult to get a concentric hole through the entire length required by a pen, so that doesn’t work too well.

While browsing their stock, though, I found some gorgeous thick-walled stainless steel tube stock. Had to buy it.

I started out without a complete plan of what I was trying to do, and it’s clear that I was just playing around with shapes.

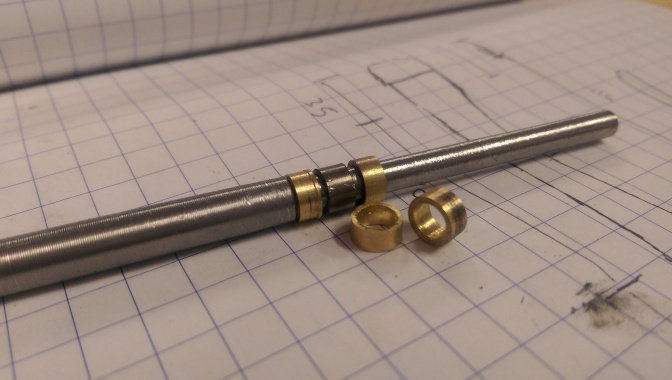

So I decided I liked that, parted off the left side, and machined some brass rings to go around the grip as extra bling.

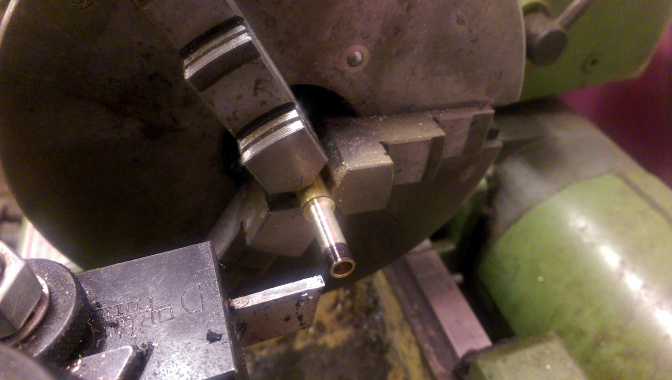

You can see the scales I was working at, this all ended up being pretty precise work. Our lathe is a little large to comfortably get in to close features with the tailstock in use, but it’s still possible when you’re careful.

This piece had no way to effectively join it to the other side of the pen due to lack of forethought, so it had to be scrapped.

The next version was a little bit better, and shows the steel-brass-steel ring pattern, and kinda how everything fits together.

But then, one of the biggest takeaways I learned on this project is that working with stainless steel suuuuuuucks.

It’s really malleable, and is able to bend with low forces, even less than an inch away from where it’s being held.

Due to the high carbon content, it’s super hard on the tools and required frequent resharpening. When the tools are dull, the metal goes straw-coloured due to heat treating really quickly, and gets even harder.

So here’s attempt number three. I’m at about thirty hours by now, but getting faster after every failure.

I’ve attempted to fix everything together with superglue for machining, but there are issues with that. I’ve seen people use superglue for all sorts of workpiece holding in brass, but brass is really soft and easy to work with. While trying it with steel, the forces are much greater, in addition to the steel getting warm and melting the glue. Basically an exercise in frustration and not really worth it (for steel).

Nevertheless, regluing often and working slowly eventually starts to get results.

Until…

Attempt number four used a separate aluminum piece that I machined into a very thin-walled tube - about one quarter millimetre walls - instead of a single steel piece, because it’s much easier to work with.

Abandoning superglue, I tried using silver solder. This was a risky prospect, because aluminum forms oxide layers that don’t adhere well to solder, and stainless steel just doesn’t wick until very high heats. So I used a MAPP gas torch, liquid flux, and silver solder, which resulted in…

My brass rings melted right off the tube. Was not expecting that.

Okay, attempt number five. This was a tube I machined out of mild steel with the brass rings, and only silver solder between them instead of alternating with steel.

As opposed to stainless steel, mild steel was really easy to work with and soldered to well. It oxidises, though, not acceptable for anything on the outside of the pen. So it needs a sheath on either end.

And then roughing it out. Superglue works fine for the final steps, because there are no cutting forces trying to tear it apart.

Filing and finishing it. So much filing. Part of the reason this project took so long is that between each of these steps, there’s one or two hours of filing to make all of my interference fits work.

Afterwards, I sanded from 180 grit all the way up to 600 and then emery paper. It was mirror finish by the end, and with a little bit of polyurethane varnish used to seal it all in.

As you can see, the idea is to hold a standard Bic pen cartridge, nothing fancy. Next pen can be more complicated, I wanted this one done quickly. Things I learned:

- Stainless steel is The Worst

- Silver solder actually looks great and is easy to work with

- Stainless steel is so bad

- Those Youtube videos where they lightly touch the piece with an emery board after they finish machining? They’re cutting like an hour minimum of work out of the video

- I’m never working with stainless steel again

I’m done with this project, but there are definitely some things I’m not totally happy with, to be fixed for the next one:

- I built a little pocket clip using spring steel and hammers , but never ended up putting it on

- There are tool marks on the front portion

- The very front edges has a little lip from the mandrill deforming it

- I didn’t let the varnish set properly, so it’s coming off a little

- There should be some tactile difference where the grip is, it turns out this pen is a little hard to pick up and use without looking at it.

Props to @Jade for saving my life with a timely delivery of more steel, cutting fluid, carbide bits, and superglue.

@Lukeo for rounding out our sandpaper collection.

Also @Shane and others for offering tips and brainstorming potential failure modes of risky steps. And thanks all for the encouragement along the way!