VHS is a wonderful place with awesome tools. It’s easy to get caught up in making cool projects that one forgets that the tools we use need some care and love to keep them running. If you see something in need of a little love and maintenance please take it on. We’ll all appreciate it!

Anyways there are a number of sewing machines that needed some cleaning, oiling and lithium grease and some tension adjustments.

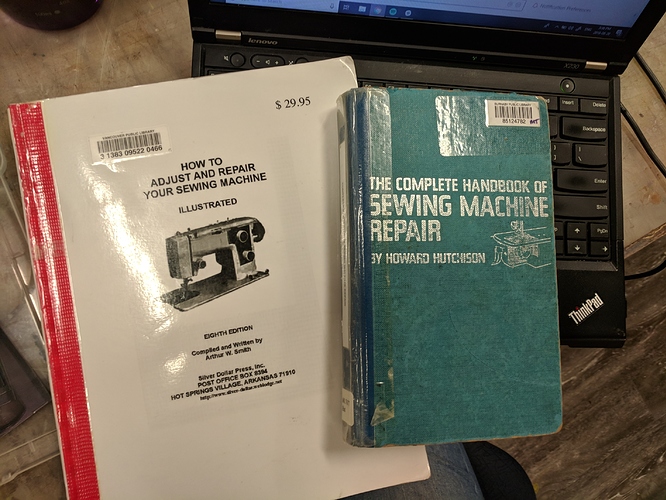

Today @Janet and myself spent the afternoon plumbing the depths of sewing machine repairs! I knew nothing about this when we started! It was a fun learning experience and now I know a bit more about the Singer 5805 machine.

Janet worked on the Kenmore and tackled the even more complex task of fixing the bobbin thread tension!

You can find out about VHS sewing machines on our Wiki

I worked on Singer and Janet tackled the Kenmore

Below are some pics!

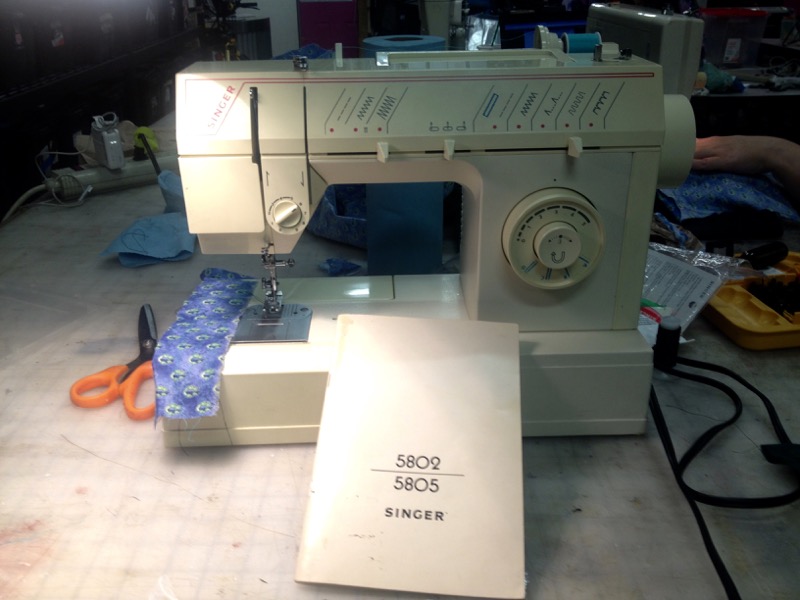

Singer 5805 with the user manual

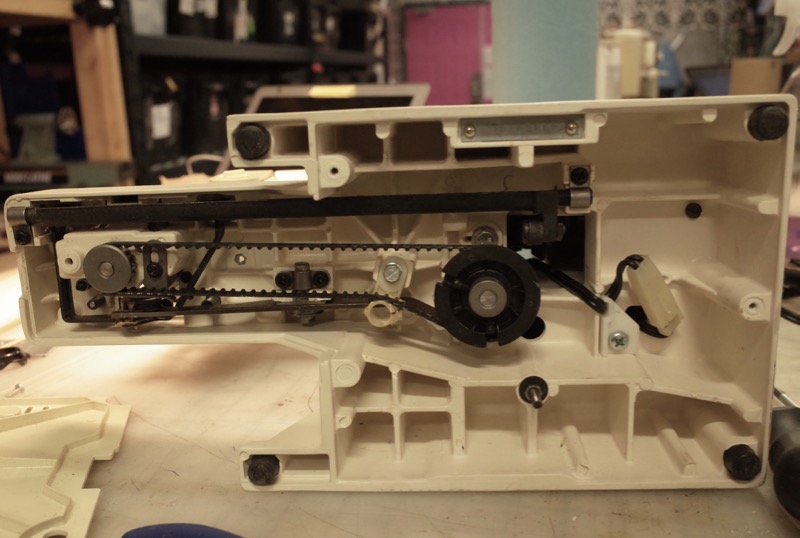

Top Cover removed to add Lithium grease to the proper spots (gears mostly)

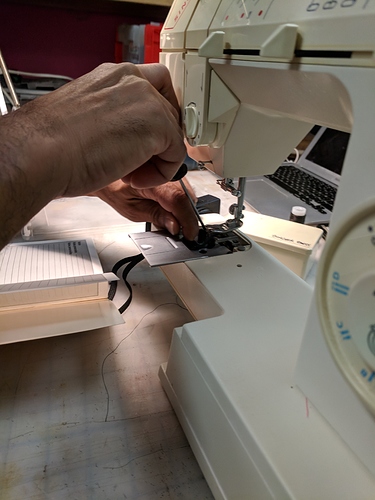

Side cover removed to allow sewing machine oil to be added at the points specified in the User manual

Bottom cover removed again for lithium grease. Belt looks in good shape.

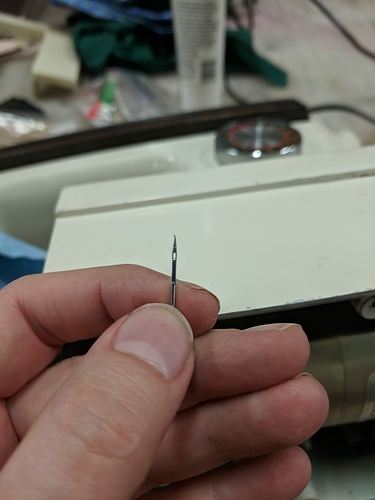

Front and back of sewing test strip. Thread tension looks good. We did notice that stitch type (Straight, Zig Zag, etc) , type of thread (Bobbin and Top) and material thickness all affected the stitch quality. It is very important that you “dial in” your settings on this machine before you begin work on your project!

Front

Back

Janet applying sewing machine oil