I’d like to share some photos of a project I recently completed at work that I’m particularly proud of.

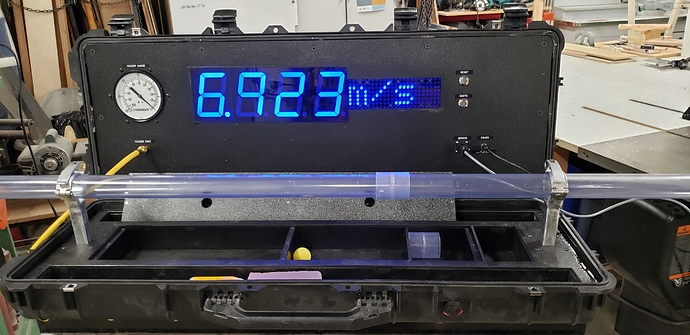

This is a ping pong ball vacuum cannon that I was asked to build for Science World’s On the Road team that travels to schools across the province to perform science demonstrations. It can launch a ping pong ball at over 1000km/h, measured by an infrared ballistic chronometer that I built specifically for this. This vacuum cannon is the 2nd version of one that I built a few years ago, and is built inside of a Pelican 1720 rifle case for portability and a high-tech/sci-fi appearance

All of the work was done myself in the Science World exhibits workshop. The black plastic panels were designed in SolidWorks and then Laser-cut out of 1/4" ABS (SW’s laser cutter has some really powerful exhaust ventilation – ABS is a banned material in the VHS laser cutter, and in the future I’d probably send the ABS out for water jet cutting instead since the laser leaves a sooty edge), and I used transparent blue acrylic to cover the LED displays.

I built the electronics onto protoboard. The speed displays are made of giant 7 segment displays each driven by a TPIC6B595 power shift register chip. I wrote my own library to parse a floating point number onto the seven segment displays. The unit displays are Adafruit 8x8 neomatrix modules. The speed is measured by two infrared phototransistors spaced 10cm apart in a 3D printed housing that snaps onto the cannon. The whole thing is controlled by a Teensy LC microcontroller board, and the speed measurement uses hardware interrupts for accuracy.

The hardest part of this project was understanding all of the different material properties. For example, the Pelican case is made of polypropylene, which I had lots of difficulty finding an adhesive that worked (I found a specific type of 3M VHB tape that works on Low Surface Energy plastics like polypropylene.). There was also learning how to TIG weld aluminum.