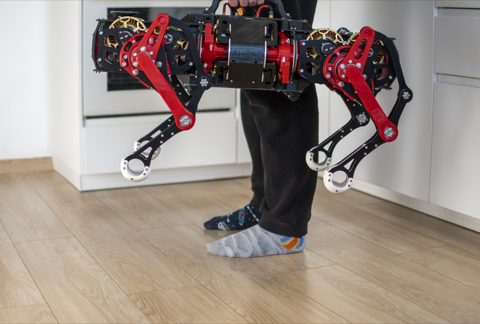

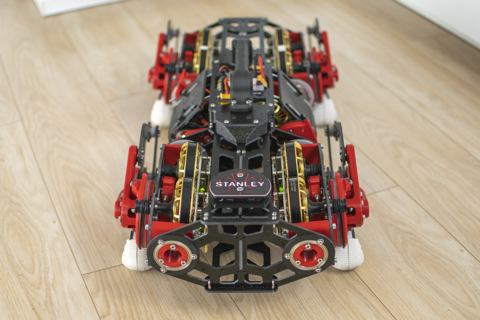

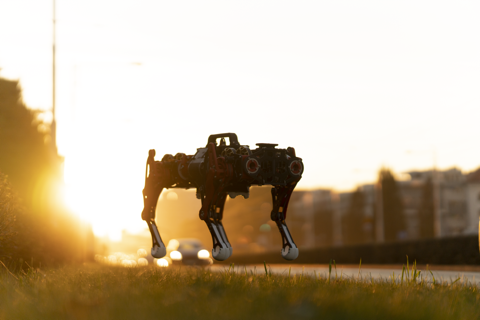

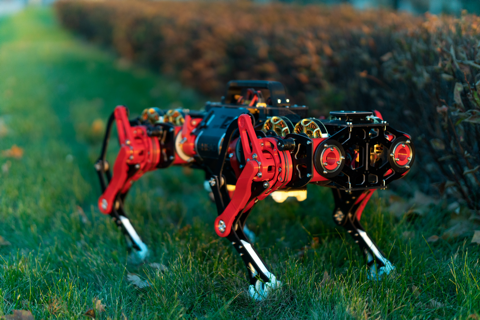

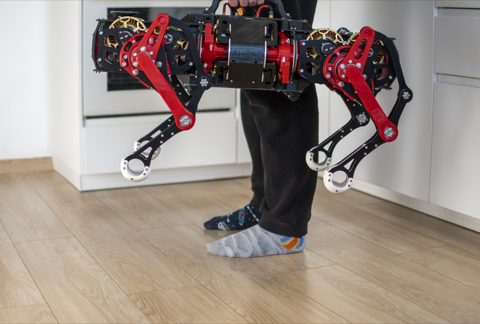

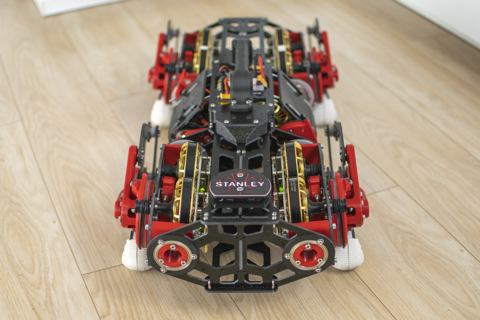

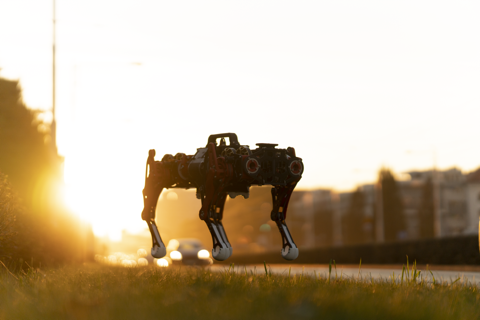

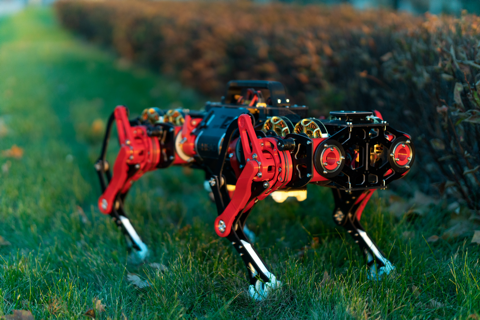

Alex provided the following images to show off STANLEY:

And their description is as follows:

Ahead

Ahead is an innovation studio based in Vancouver. Our mission is to imagine and create novel technologies that look into the future and that ultimately enable a healthier planet and enrich people’s lives.

We are a mix of creative thinkers, artists, engineers, scientists. We combine our knowledge and experiences to turn ideas into tangible products. Some ideas rest with us, hidden in our drawers, whiteboards and attics, others become public knowledge.

We started our journey as a creative engineering consultancy studio solving vision and image processing challenges for the industrial and the film & entertainment industries.

We are best known for Cezanne, a state-of-the-art image visualization software for the creatives.

We are the maker of Stanley, the first Canadian quadruped robot.

Why quadruped robots?

We began the pursuit of this dream two years ago, doing research about connecting and programming real devices through a mirrorworld.

We wanted to find an affordable and modular quadruped robot to use for our own research, and quickly realized that we were not the only one.

With Stanley kit we want to make robotics research more affordable and create a new learning tool close to more sophisticated industrial quadrupeds, allowing anyone to further develop quadruped robot behaviors and scenarios.

Our ultimate goal is to develop a robot that can be used for forest exploration, and wildlife conversation. Forest fires are increasing and we believe having robots that could inspect remote areas of Canada, would allow prevention, and help in high risk operations.

Stanley

Stanley is a maker friendly quadrupedal dynamic walking robot. It is the first commercial quadruped robot made in Canada and the first one using capstan drive on all axes.

Stanley is currently available for sale as a kit. The kit comes with a guide that helps the maker to assemble Stanley while learning all the choices we made to create it and get an understanding of the various layers that make Stanley mobility and behaviors. Preassembled and custom versions are also available upon request.

All of the Stanley’s parts are either 3D printed, standard off-the-shelf, or CNC 2D routed in FR4 and aluminium plates. This makes it very easy to modify and repair, as well as providing a fun and engaging assembly process.

It uses twelve motors controlled by twelve custom drivers giving twelve degrees of freedom, to allow the four legs to have three degrees of freedom so that the pointy end of the feet can achieve any commanded positions in cartesian coordinates.

Stanley’s legs utilize a parallel rigid link mechanism to actuate the knee joints which minimizes inertia and maximizes mechanical rigidity.

Stanley is capable of about 2.5 kg of load and weighs in at 14 kg. It uses 2x 5000 mAh 4s batteries in series, which allows the user for about 45min of fun depending on the load and how hard it is used.

Free mounting holes all around the robot will allow future users to mount accessories, like cameras, speakers, gas sensors and other 3D printed accessories, people may like to create for their research or just for fun.

Stanley as a learning and research tool

Stanley’s main purpose is research and education in the fields of mechanics, robotics, machine learning, reinforcement learning, artificial intelligence, computer vision.

Stanley has been developed primarily with makers and university researchers in mind but is also an amazing learning platform for high school students starting from grade 8.

It’s built in a way that students can take it apart as many times as they want, allowing schools to use one robot for multiple teaching cycles.

We are currently working with various universities and high schools integrating Stanley in their courses.

Where can I buy a Stanley Kit?

Stanley is available for purchase by contacting us at sales@ahead.io

Where do you make Stanley?

We have run as a distributed team since the early days. It has been easy while running as a software company but once you introduce hardware in the mix, you really need to consider the bolts and nuts of the entire operation!

Stanley is designed and perfected in our home offices, between Vancouver and Montreal in Canada and Wroclaw, Poland. The final production and kit packaging is currently made in Vancouver.

We are currently looking at the right province in Canada to regroup the whole team and set up our lab and manufacturing…

Who funds Ahead?

We are completely self funded. Our clients are our main investors. We don’t waste money on things that don’t matter, we don’t give away everything for free and hope we’ll figure it out before we run out of cash.

Contacts

Youtube : Ahead.IO (https://www.youtube.com/channel/UCtpbQvb6vQvS75QQCAhiEOA )

Instagram : @aheadgarage ( https://www.instagram.com/aheadgarage/ )

Twitter : @ahead_io ( https://twitter.com/ahead_io )

Linkedin: @ahead-io (Ahead.IO | LinkedIn)

Hashtags for Stanley: #stanleyquadruped, #stanleynftart, #aheadgarage, #thinkahead #aheadio

Hashtags for Ahead.IO: #aheadgarage, #thinkahead, #aheadio

Website : www.ahead.io

Email : info@ahead.io