Hi fellow Piccolo builders!

@Andrew_Hendriks @3bien @lukecyca @jarrett @mkobie @jon_slaco @Janet @sIGNgUY @johnbiehler @jon @funvill @packetbob @RandyNW @johnbiehler @interlock

Tonight @jon and I took a crack at test fitting a Piccolo. Here’s how it went down:

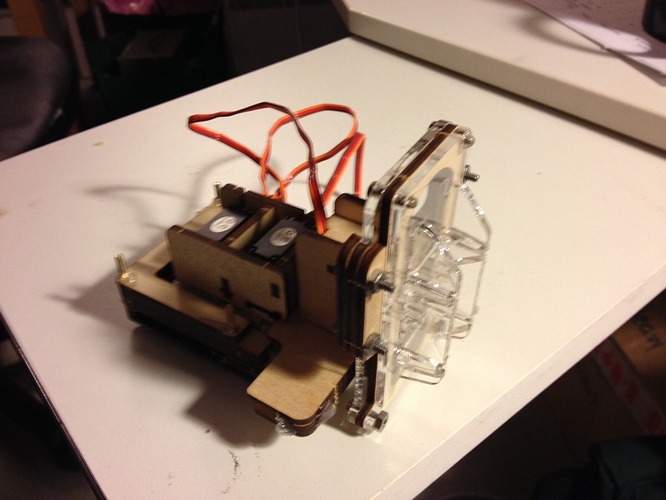

We cut the chasis/body using 3mm plywood we found (checked carefully for no name), and the 3 mm acrylic provided by @RandyNW was used for the gears and tool holder.

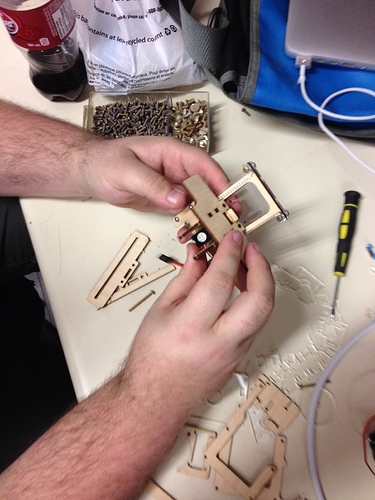

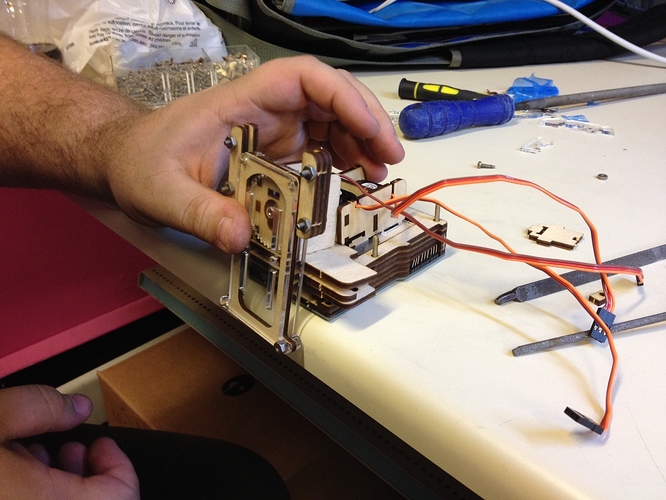

Assembly in progress. We didn’t have the special low-profile M3 nuts and bolts, so we just loosely put it together. @Jarrett has mentioned making a bulk order from Fastenall I believe, can he confirm?

Final fit.

Experience report:

“Makes you appreciate how clear LEGO instructions are.”

The fit of acrylic and plywood seems good. We used my board, and it looks like there was a height problem on one of the capacitors such that the y axis gear strikes it. Plan to fix this using the GSM 90 card spacers that we laser cut.

Don’t forget the X3 component (looks like a capital I or bow tie) in step 6, it’s easy to overlook.

During a test run of the spiral demo program, if the motors stall they appear to draw too much current for a regular USB PC plug. This causes the voltage to drop too low for the Arduino and it will shut down. This can be solved by using a powered USB hub, but you still need to solve the motor stalling problem. In this case it looks like the motor was in the wrong position and hit the end of the track.

Summary

I’d like to suggest that people hold off on cutting their own until we can verify that the test Piccolo build is stable. To do that I need to get the proper nuts and bolts and assemble it, then let it run itself ragged.

The files for the chasis and the gears/tool holder are all now on the laser cutter computer. I’ll ask @jon to post the exact filenames so people can find them.

All the materials (the plywood and the acrylic) are in the materials storage, labelled “Piccolo.”

The GSM 90 card spacers (provided by @funvill) are in the locker with my name.

Special thanks to the laser cutter committee (@rsim, @garthomite, @jon) for getting the laser cutter operational!