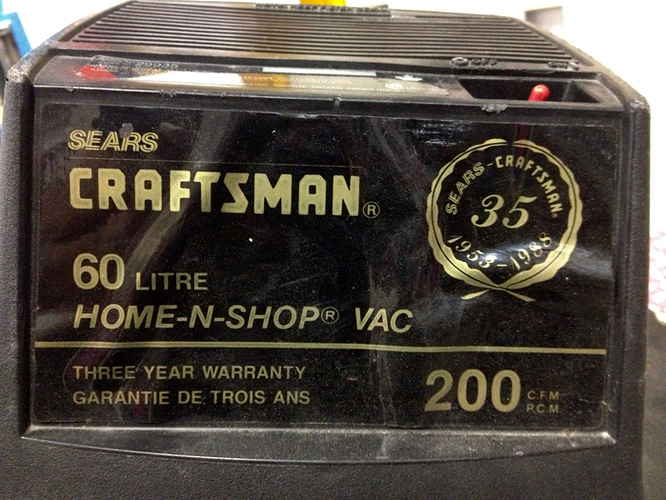

I dropped off a Shop Vacuum needs to have the power cable reattached. I didn’t have time last night to fix it. Also need to find a new filter and a hose. But apparently works well, when its running.

Thanks Dan - I’ll take a look at it tonight

Who wants to permanently install this along with a two-bucket cyclone, and duct our woodshop tools into it?

I’ll lend a hand. I’ve designed something similar for the powder printer but I’ve been meaning to improvement on it.

Looks like most of the plans there are for making your own blower. I’m familiar with wandel’s work and a lot of people have copied and created different derivatives. His advancement was the adding of the baffle to separate the collector area at the bottom from the air flow at the top. I’ve seen better systems though that employ a cone at the top the funnels all the debris into the bottom tank. better because most of the air flow never gets into the bottom so the debris settles in and stops moving.

I use the 2 bucket type system because you don’t even need to secure the bottom bucket and just pull it off to dump it.

There is a post on Hackaday about filtering Laser cutter ouput. The comments brought up a good idea: Use a humidifier filter as a pre-filter. It helps by condensing the fumes and doesn’t clog the filters or charcoal as quickly. Activated Charcoal | Hackaday

The Vac is looking awful lonely these days. Any plans to proceed with this or should we send it on the the great vacuum in the sky?

I was going to work on it last weekend during the open build because I didn’t think it would be so busy. I was wrong of course.

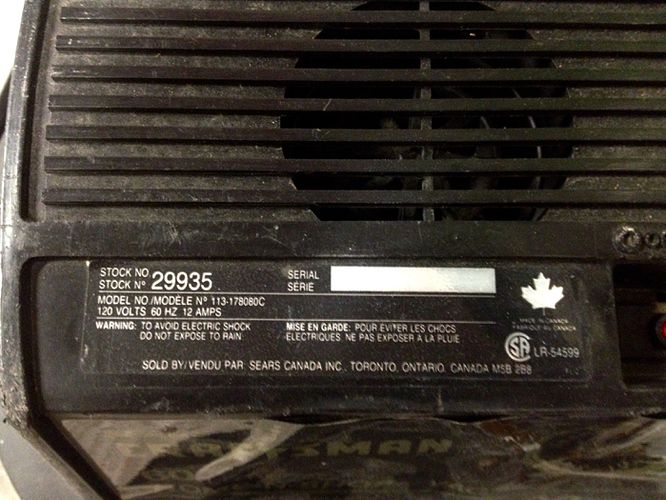

Actually if your down at VHS atm. Whats the brand name and model of the vac? I need to google it to see if I can figure out how to remove the motor without breaking it.

Hey Dan - I was curious so did some googling and found this video. Maybe some oil would do the trick and then you wouldn’t need to tear the motor down.

I will have to take it apart still. The wires were so corroded that they were green inside the entire length of the power cord. Not a good thing.

But I did finally find the manual

www.manualslib.com/download/476420/Craftsman-113-178060.html

Doesn’t say it outright but does seem to indicate that the plastic blower fan should be able to come off. When I’m down at the VHS which will be soon but not till after the snowfall I’ll try to see if I can remove it without breaking it. If that fails its off to the junk yard.

But thank you for looking.

Ah…yeah with that corrosion. No worries - it’s interesting for me also. Will check out the manual.

Marius Hornberger just put up a nice cyclone video a couple weeks ago as well, I like how small this one is.

There is a different design I was looking at as a dust collector.

There’s a video on Youtube how to make one. But my first attempt broke the plastic I was trying to use. I need to find more flexible plastic to use.

Finally got the vac apart last night and replaced the bad wires. Just haven’t gotten it back together yet because I have to make some kind of jig or something the keep the brushes separated so I can reinstall the motor. That and try to remember how the whole thing was wired.

sorry wrong post lol