Inspired by @packetbob documenting progress with Eddie, I figured I could share my journey of making a led Rubik’s cube from page to reality. I’ve always loved Rubik’s cubes, although up until about a year ago I was never committed enough to learning how to actually solve them so the one I had as a kid stayed untouched on display. After being sparked to actually learn more cube skills I figured that I should do some sort of led project that both would highlight my skills as a lighting programmer and designer, and be a fun one of addition to my growing collection.

So!

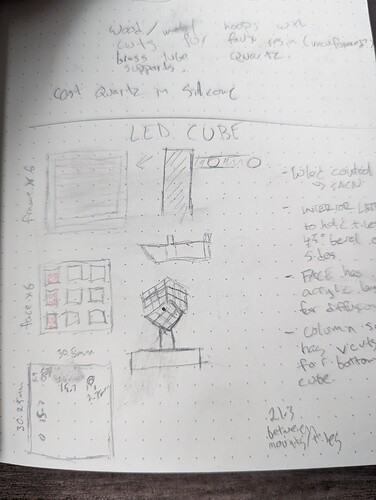

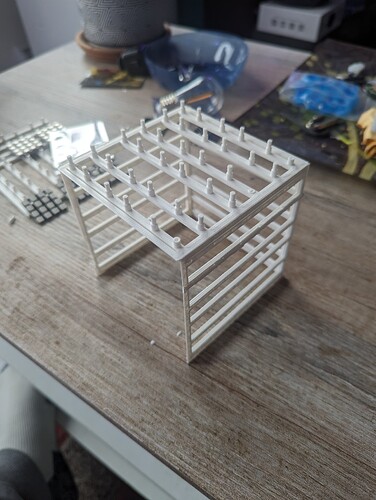

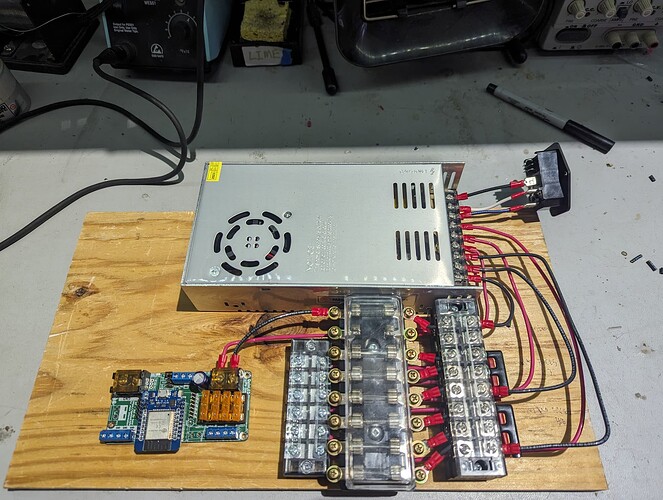

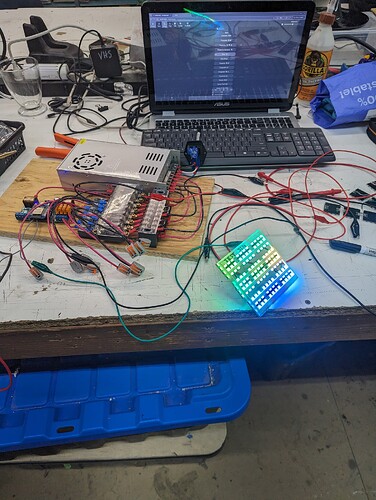

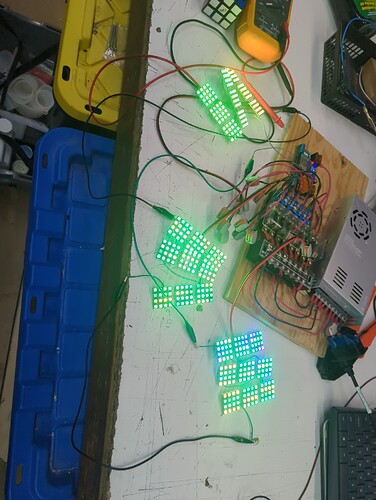

Opening up my journal I did some thinking, some sketching, and some late night rough measurements of what I wanted: a cube on a stand, where each face contained a 12x12 pixel matrix, with the idea being that I would control the ‘movement’ via simple button press; one button for each clockwise and counterclockwise clockwise of the 16 different possible actions.

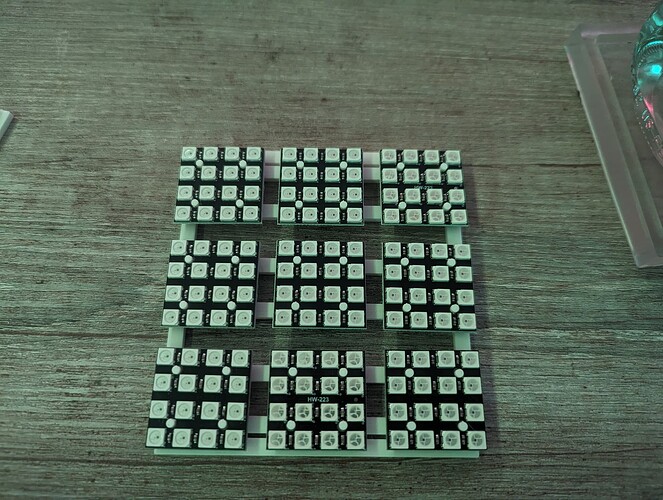

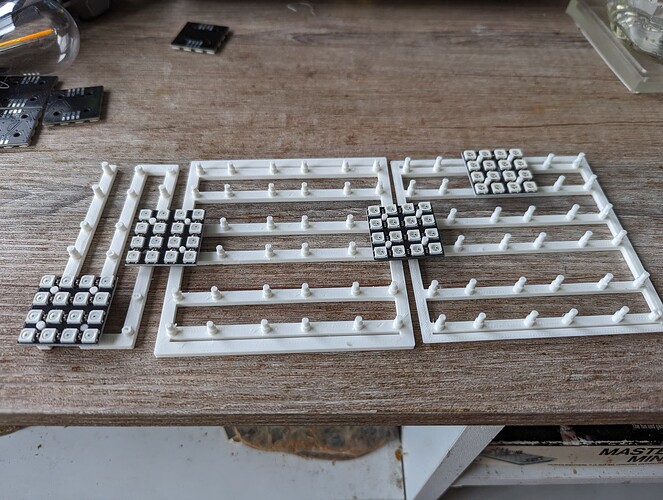

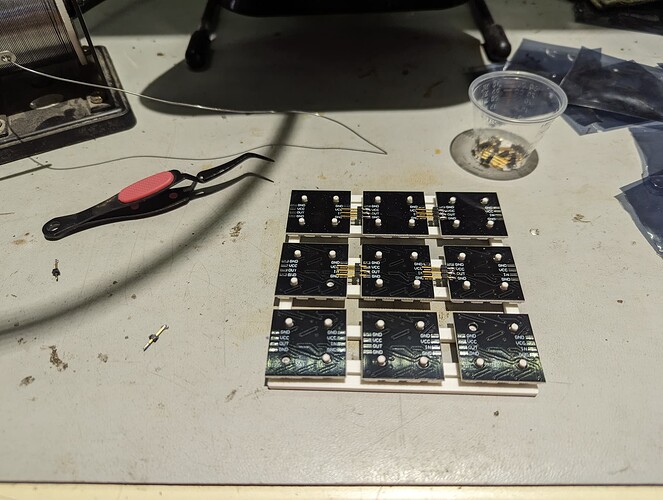

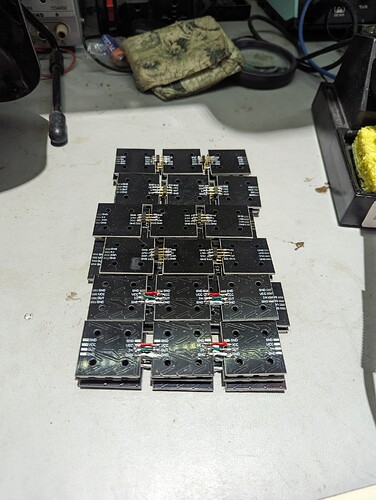

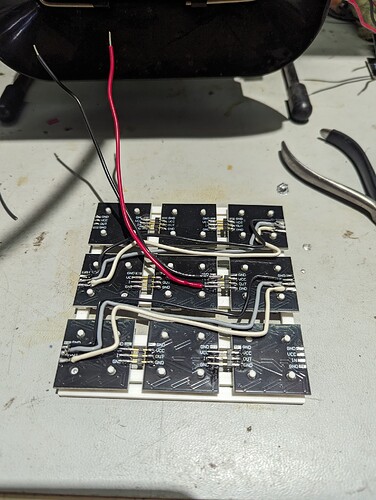

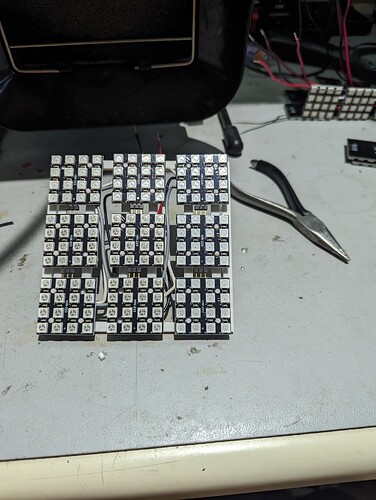

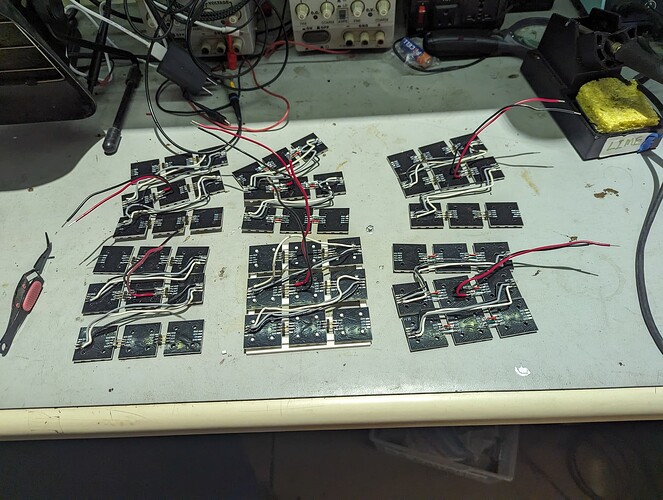

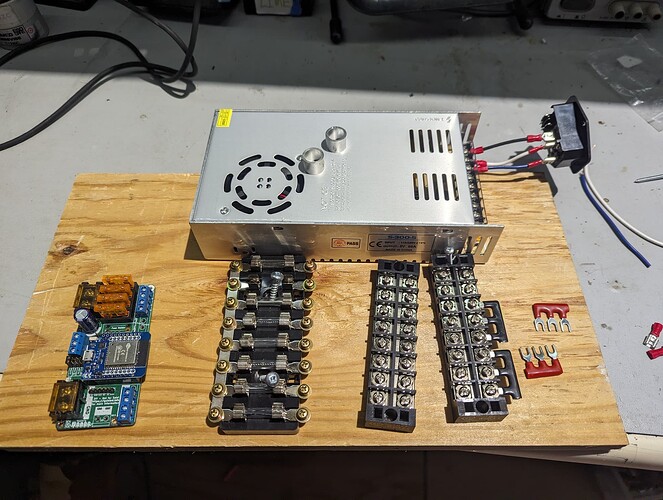

I decided that the best plan would be to have a grid of 4x4 ws2812 led tiles on each face, with a frosted acrylic panel to hide the components, and a faceplate grid to outline everything and sell the Rubik’s cube aesthetic.

Pleased with the idea, and some encouraging direction in jumping from printing other people’s models to creating my own from scratch I put on my comfiest maker coverings (a kigurami otter onesie), found a Spotify playlist for 'epically inspiring 80’s montage playlist, didn’t like it, put on my all rush mix tape instead, grabbed a 2l of Shasta and got to rocking!

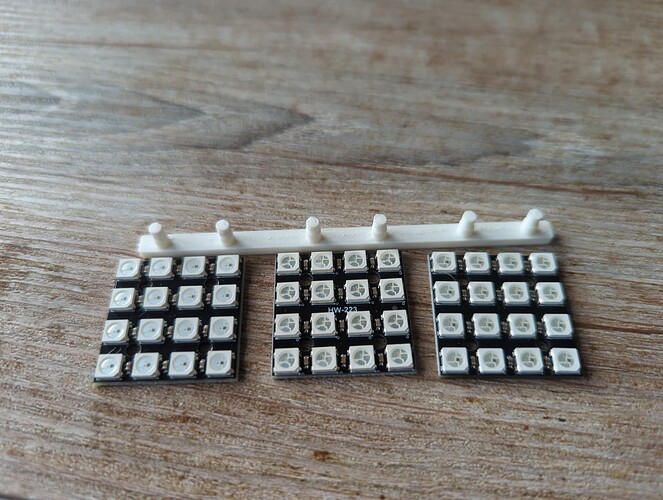

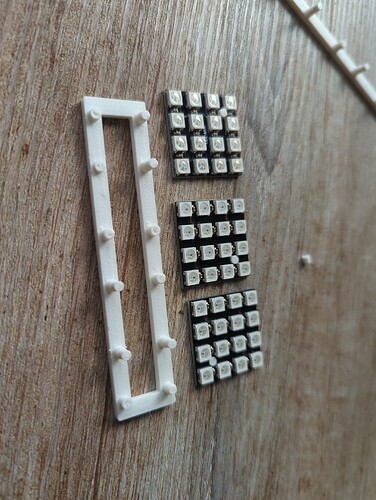

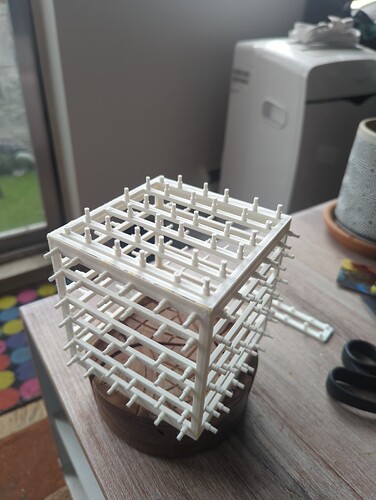

I first wanted to make sure that I was happy with the spacing between tiles, celebrating making a successful baby’s first 3d print in about 15 minutes that did exactly as expected.

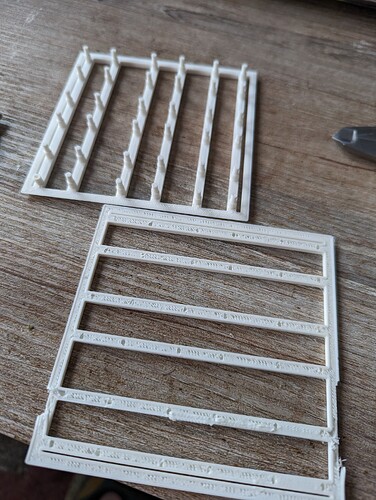

Surprised and encouraged by the accuracy I carried on and made myself a single row frame to make sure my measurements were correct on both axis. A flip of the cassette and a bit more zero cool cosplay and I had done it! A frame fit for a… Set of led tiles to rest comfortably on.

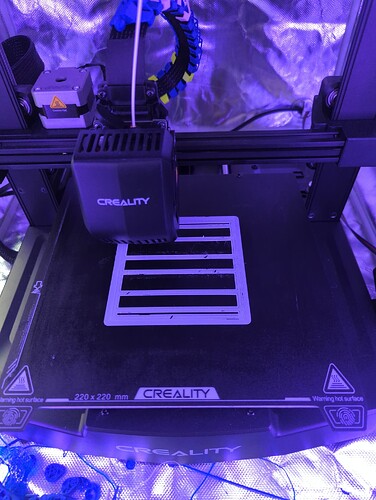

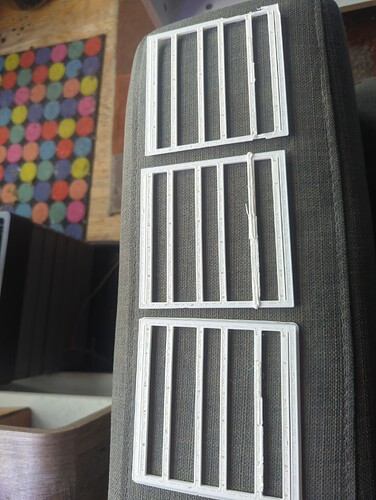

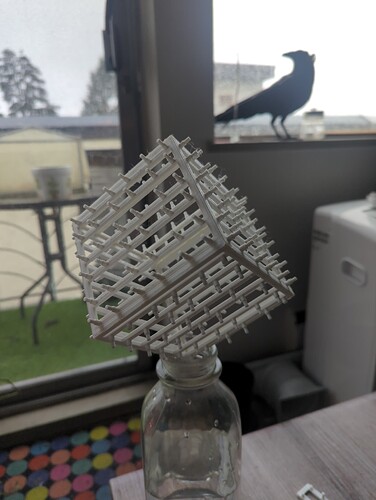

I used this time to ponder on the distance between the edge of the tiles and the edge of the frame for a moment and continued merrily down the rabbit hole of cad revisions and schematic improvements; tweaking this, and shifting that until I was peering at a Cura slice of something I was anticipating holding aloft like a Simba plush on my balcony. I lit a candle as offering to the makers maker, said a silent incantation to ward off the deamons of printing errors, and hit ‘confirm’.

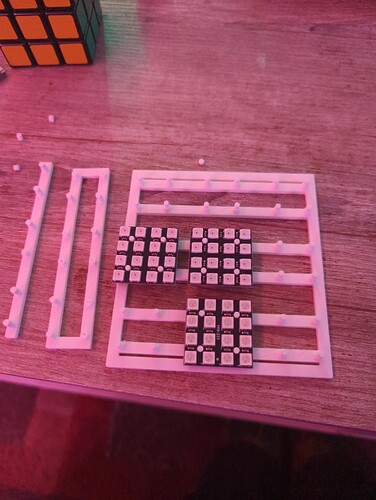

KOOLADEMAN.GIF!

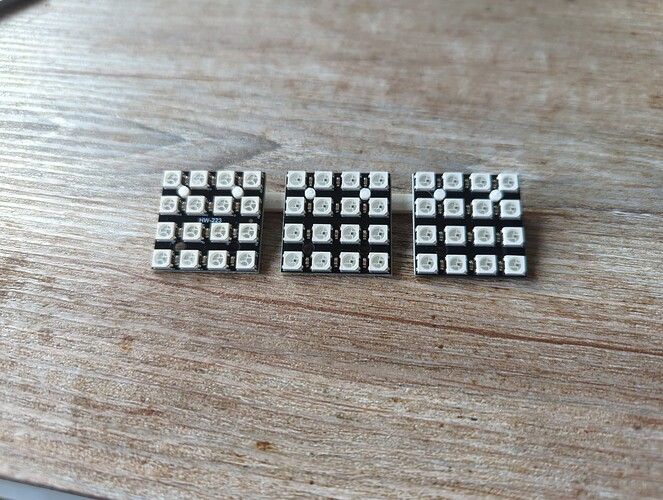

I felt like macho man Randy Savage snapping into a slim Jim! The test print was a complete success. I was happy with the spacing between tiles, the distance they were offset from the frame is perfect for the wiring to fit in, and the two distances used to offset the frame from the tile edge provided lots of useful information to sleep on

Next up I’ll be needing to bevel the bottom of the frame so I can fit 6 together without weird overlaps, change the frame dimensions slightly to reflect the edge distance, and begin thinking about how I want to attach the frame to the base while still allowing wire pathing and access for connections!