OK I’ve been on slack posting about the knives I’ve made. So I’m starting a thread to document how I am doing this, I’m not going to document the design process, but how I’m actually making them.

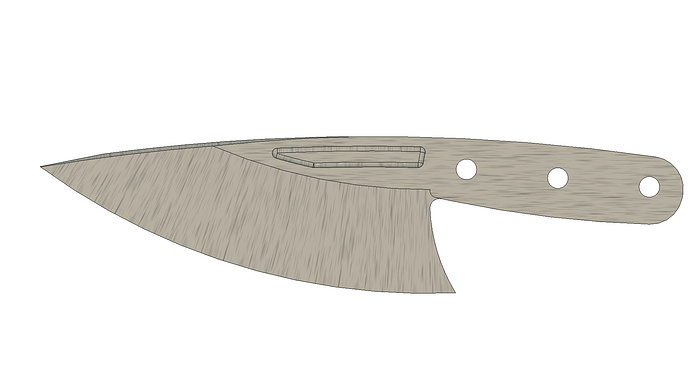

Here is a shot from Fusion360 of the knife I’m making now.I’ve selected S35VN as the steel. It’s created from powder kind of like Carbide inserts. Pressed under heat supposedly to achieve a more uniform grain structure. This isn’t a crazy expensive steel, but it isn’t cheap either. 3/16" x 2" x 12" runs about $73. The first step is to cut the blanks to length on the horizontal band saw. I’m not posting a picture of this as it’s boring. Please also note, I’m doing this in my machine shop, not @ VHS as I have almost all the tools I need here, and I’m not sure of the policies on some of the tools in regards to steel. Especially the saws. ![]()

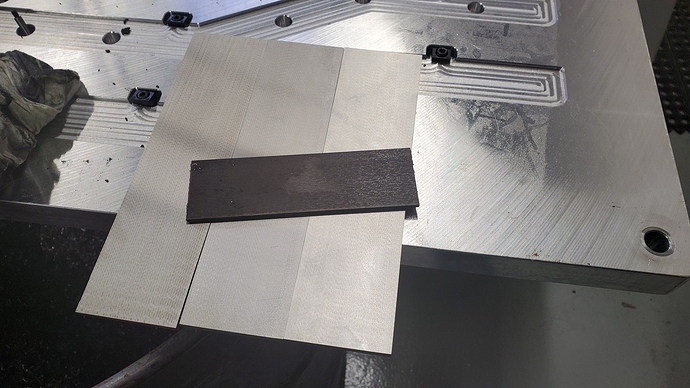

After cutting, the stock thickness comes over size, so I’m surface grinding to thickness.

.This is where I’m at right now. Next step will be machining. I want to design a plate fixture where I can have all 3 operations up on one plate in the machine. Stay tuned for updates.