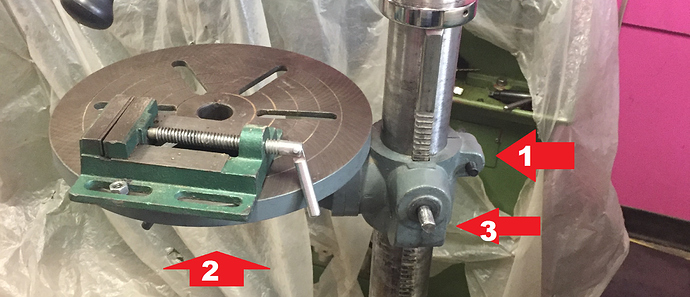

So VHS has a good drill press right beside the laser cutter. Unfortunately, the adjusting rack which raises and lowers the platform was badly bent. So I spent a few hours carefully bending it straight and reattaching it. Here’s what it looks like now:

Although the handle is missing, it does not take a great deal of force to raise and lower the platform.

- Loosen the bolt (#1) on the back of the platform

- Lift the platform (#2)with your hand

- Turn the knob (#3) in the desired direction of travel with your other hand

- Tighten the bolt (#1) to hold the platform in position.

Do not put a Vice Grip on the knob (#3) as a handle; you will destroy the shaft!

Also, the table should not be shifted left to right; move the work on the plate instead!

I also noticed that the drive pulleys were misaligned, and the belt is pretty chewed up. Note how much higher the rightmost pulley is:

After consulting with more experienced machinists, the belt is unusable and should be removed immediately. As a result, the drill press is out of order until a replacement belt is acquired.

The belt required is:

M-24 0503 46

I have put an Out of Order sign on the drill press.