Hey folks, Andrew here. If you’ve used a lathe at VHS, odds are we’ve been through training together. Lathes are cool!

I was hoping to bring this to the membership earlier, but discussion amongst the Machine Shop Committee has been ongoing. Concerns were raised, they’ve mostly been addressed, but as of this post the committee has not yet reached consensus.

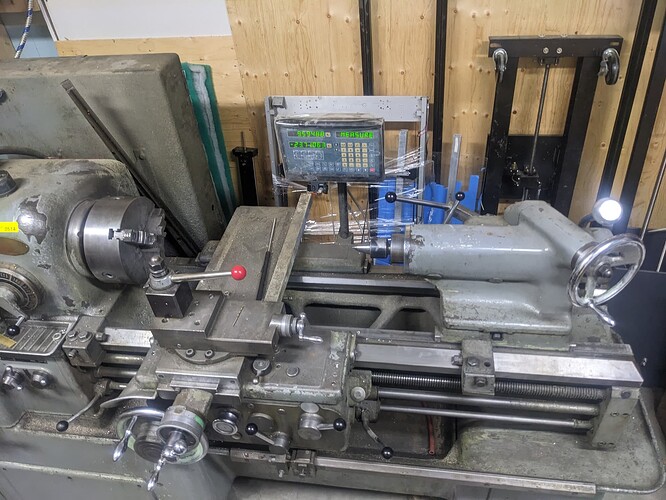

Couple weeks ago, I came across an auction listing for a rather nice-looking Okuma lathe. This was a high-end machine when it’s new, and it’s still comparable to high-end manual machines available for today. To keep traffic down, I won’t be posting the auction listing, but I’ve included photos I took at the preview yesterday. Its footprint is incrementally larger than the Frejoth.

I went to check out the machine yesterday, brought a friend of my uncle’s with me, who used to own and run a machine shop in town. He spoke highly of Okumas in general, checked out this machine, and said it was in very good condition. I’ve run it under power, we’ve confirmed that everything works.

It also has several accessories included that we’ve identified as being useful at VHS. This includes a 4-jaw chuck, a DRO (Digital ReadOut), outside jaws for a 3-jaw chuck, and a smattering of other accessories. Lots of things that are particularly useful to have in a machine shop. It’s also a more powerful machine, and has an 1800 RPM spindle, which is better for small parts.

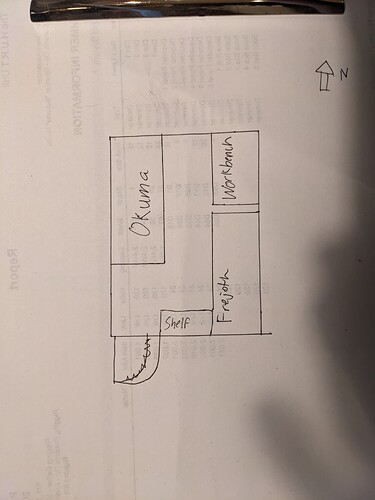

I originally suggested we consider transitioning from the Frejoth to this Okuma, but understood folks were uncomfortable wtih that idea, which converted the plan to dueling lathes. I’ve prototyped some reconfiguration of the machine shop, and confirmed that both machines would fit well, without having to move and re-bolt the Frejoth. My proposed configuration puts the machines kitty corner to each other, so both machines could be operated simultaneously, by separate operators, without interfering with the other.

Logistically, I understand the previous lathe took several months to bring online, and that raises concerns. This isn’t the case with the Okuma. It’s confirmed to operate under power, and no major maintenance is required. All that’s needed is to roll it onto the machine shop, drop it onto the floor, plug it in, and flip the switch. Because of the rigidity of the casting, it doesn’t even need to be levelled before making chips. I understand folks’ hesitancy given last time, but it wouldn’t be unrealistic for the Okuma to make chips the day it arrived.

For training, a half-hour orientation should suffice, similar to the training Old Lathe users receive before using the Frejoth. As of this post, I’ve run the vast majority of lathe training, there is currently no backlog. I have a good track record, and intend to keep that maintained.

Financially, I’d be purchasing this machine and placing it on loan, so there is no cost to VHS.

It’s also worth noting, the Frejoth is in need of maintenance. The cross slide nut needs to be replaced, the power feed rod needs to be straigtened, both of these require a fair bit of disassembly that’ll put the lathe out of commission for a bit. Having a second machine in the shop covers this downtime.

And now, if you’ll join me in "ooh"s and "aaah"s:

And hey, ALL the hand wheels are metric! And the tick marks are there!

y

- Yes, bring in the Okuma on loan.

- No, don’t bring the Okuma in.

- Undecided/Turnip.