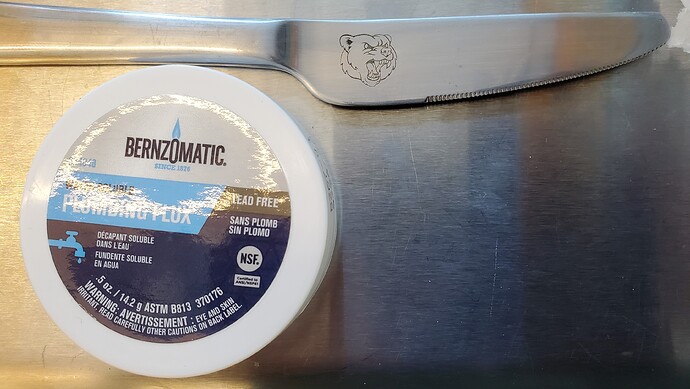

With students finished for the summer, I have plenty of time to experiment with stuff in the university maker workshop I supervise. One of the other lab techs came by wanting to experiment with marking stainless steel on the CO2 laser using a mustard coating, something he had come across on Hackaday. Results were not impressive so we started looking around the workshop for other acid-based things we could coat the SS with. A few failed experiments later, we tried smearing a thin coat of plumber’s acid flux on the SS. We were shocked with the results. So far it has withstood heavy washing. We were using an 80W laser at 100 power, 5 speed and 1000 Hz. Probably not a replacement for Cermark, but definitely worth further experimentation.

That’s pretty good. There’s a demo piece in the display cabinet of a similar process I played around with 4-5 years ago. The active ingredient in cermark(extremely expensive) is molybdenum disulfide, which is also the main ingredient in dry moly lube (extremely cheap). I tried out two or three different kinds, and came away with the excellent results on display. Unfortunately, I lost all my pictures, so I don’t know which dry moly lube was the most effective.

It also didn’t work on aluminum at all, only steel. That might be because of the oxide coating, or the better thermal conductivity. That might be solvable.

2 posts were merged into an existing topic: Laser Material Approval Request: Metal Etching Agents

This topic was automatically closed 365 days after the last reply. New replies are no longer allowed.