Tried making some precision cuts on the laser today, noticed the laser was cutting a bevel, suggesting the beam is biased slightly to the southwest. I ran the tape test right before the mirror above the cutting head, the gantry mirror is out a bit, and I suspect the head mirror is out as well.

While I was engraving, the laser also threw an alignment screw out of the head. I put it back, but obviously not adjusted to the same place. However, it’s important to note that the bevel existed before the laser threw the screw.

In my personal (non-LCC) opinion, the laser is still useable for non-critically dimensioned parts, particularly on thinner materials. If your tolerance is over 10 thou (0.25mm) I wouldn’t expect to run into issues.

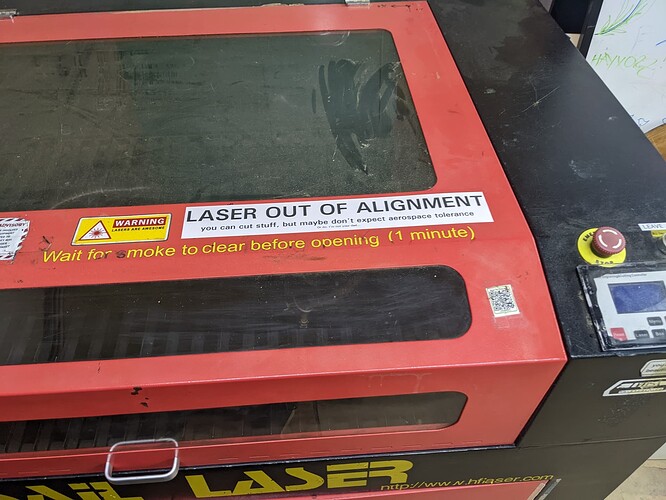

I attached a label to the laser alerting users to the issue.