Over the years I have accumulated a fair amount of broken LED xmas lights. It continually ticks me off how crap these are made with essentially a design for failure. I have some 15 year old strings that still work fine as they are sealed and not designed for replacing the LEDs (which essentially will last forever with the average holiday usage). However now all the strings have replaceable leds and that means water easily gets into the socket and quickly corrodes the LED lead. For me this can seem to happen in a single season (very wet North facing yard)…

I have tried determining the failed LED using a AC detector (like an electrician uses) but had no luck (probably cuz the AC is rectified for the LEDs). I have searched for a DIY solution but not found anything…

Saw the LED Keeper product and figured it was worth a shot. Pricey for $39.00 but I have a crap load of failed light strings so decided to get one…

https://www.canadiantire.ca/en/pdp/led-light-keeper-repair-and-diagnose-kit-7-pcs-1513440p.html

Turns out they are really hard to find… Was looking in a Canadian Tire that had no stock and saw a just opened box that had some… Grabbed one and made my way home. Pulled out one of the failed strings and it worked!! I was able to quickly locate the failed LED…

Then after the first string a problem. It no longer seemed to work. I thin discover the little wire piercing probe had broken after checking perhaps 5 LEDs… Crap!!!.. Thought perhaps I was a bit too ham fisted in my zeal to fix my lights but did a little searching and it seems to be a common issues. The maker actually sells replacement probes but doesn’t look like anyone has them (least not in Canada).

Then figured I`d return it and get a new one… Well they appear to be sold out in the Lower Mainland and the only place that has em is a Canadian Tire in Tsawwassen. Did not want to make that trip…

I then ripped it apart wondering if I could make a repair. The insulation piercing needle is replaceable but the assembly is all plastic and I figured it will not last long anyways. Thought of using a nail or something and then started looking for an insulation piercing test probe. Found some on AliExpress but that doesn’t help me fix my lights tonight. Then I remembered I had a spare set of test probes that were pretty sharp and dug them up. I jury rigged up everything and it worked fine. The hole it makes in the wire under test is a bit big but seems to close up after a while…

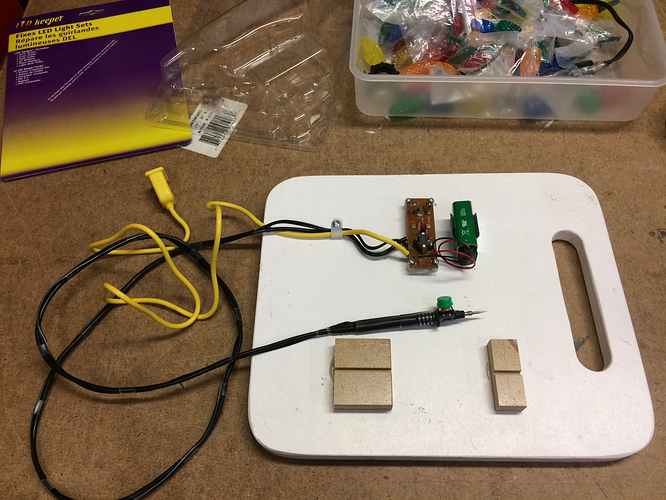

Now a string of wires has some mass and in my kludgey testing I managed to have it all fall to the floor several times. So I decide to stick it all on a hunk of plywood to give some stability. I also added a remote power switch on the probe using a little push button hot glued and heat shrinked to it. And added a couple pieces of MDF with a groove cut it to hold the wire, this makes it easier to hit the center of the wire with the probe and less likely to stick myself if I try to hold it in my hand (which I managed to do 3 times)…

Anyways it is now functional and I can try to fix my strings. The way it seems to work is by sending a low voltage current limited 8Khz AC signal through both prongs of the strings plug. Then you probe the LED wire (not the AC passthrough wire) at various points. If the string between the plug end and the probe location lights up then all is good to that point. Eventually you narrow down the failure to a LED and you can replace it (if you have spares and the socket is still good) or cut out the socket and replace with a 330 Ohm resistor and heat shrink tubing (the maker sells modules for this but its just a resistor on a plastic puck with insulation piercing prongs).

Assuming this turns out to be a viable way to fix the LED strings I`ll try mounting it in a box for next year…