VHS has a Frejoth F1 900AG manual metal lathe and many people on the machine shop committee have been working hard to get the lathe cleaned, restored, and upgraded for member use. Here’s how we made new “rubber” way wipers by 3D printing flexible Eryone TPU filament on a stock Ender3V2 bowden tube printer.

The Final Product

Our old bashed-up wipers:

Why wipers?

They keep metal shavings from getting under the carriage. Wipers need to endure sharp metal bits, oil, and general wear and tear. Our old wipers were beaten up and one was missing. Time for fresh new ones

Step 1: Design from old wipers

Luckiy we had some old wipers that came with the lathe. One of our members, @winegummo made new designs and did several careful test fits in PLA to get the design just right. Thanks Jim!

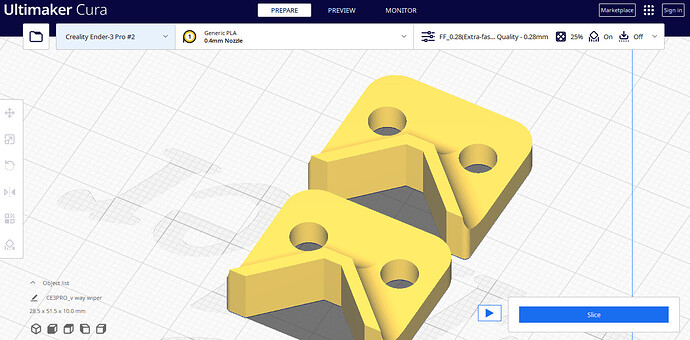

Step 2: Printing new wipers

Next we used a roll of Eryone 95A TPU to print the design on an Ender 3V2 printer. We bought fairly hard TPU as it’s the easiest to print with on a bowden tube printer. Although TPU is best printed on direct drive printers, the first test was very good. After a few tweaks to refine the settings, mostly to add extra walls and top/bottom layers the results were excellent!

Way Wipers STL Files & Printing Profile

Jim has shared his design files with us and anyone else who needs to print these parts. Thanks Jim!! If you print these, remember to duplicate and mirror image the designs to get a complete set of 4 wipers.

Downloads:

v way wiper.stl (43.8 KB)

flat way wiper.stl (25.7 KB)

Printing Profile CHEP TPU (our changes: 2-5 walls, 5 top layers, 5 bottom layers, 50% infill)

New wipers installed on the lathe

How to 3D Print TPU

If you want to try printing flexible prints in TPU at VHS, give it a try on the Prusa clone printer. You will likely have to try a few prints to tweak the slicer for the Prusa. Just use similar settings to those specified in the CHEP TPU Cura profile above. Have fun!