So I installed Fusion 360 yesterday, and I am suitably impressed. Their parameterization engine is excellent, in particular.

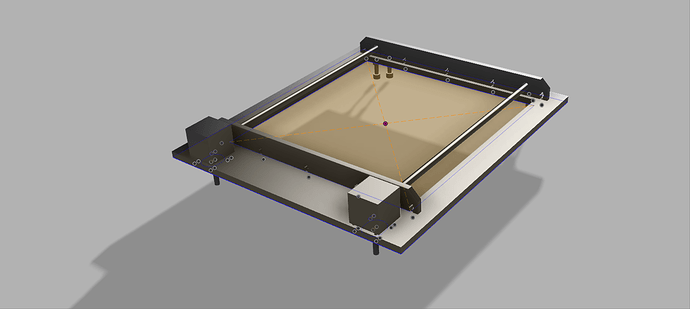

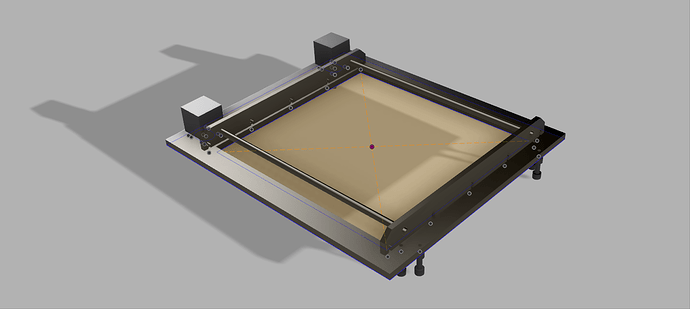

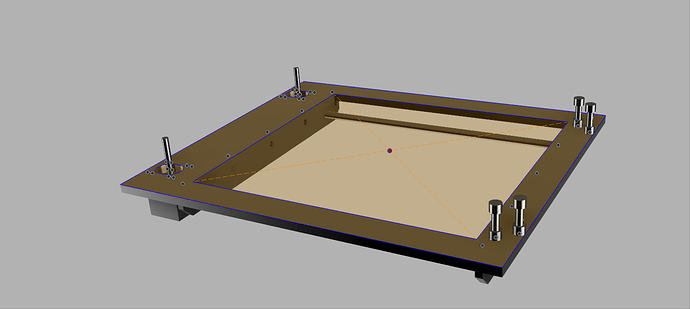

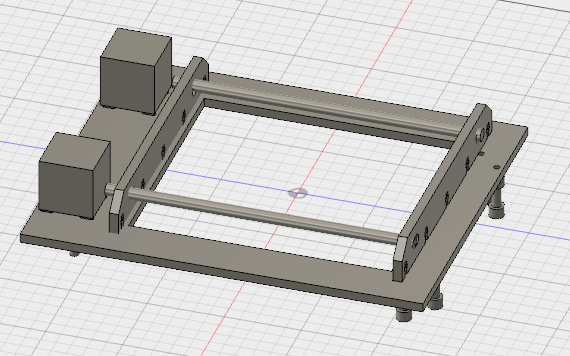

Using the CoreXY waterjet version as reference, I’ve designed a version that is almost entirely parametric. That means that there are no hardcoded dimensions, the model is built entirely out of formulas based on the linear rod lengths, motor size, hardware type, etc.

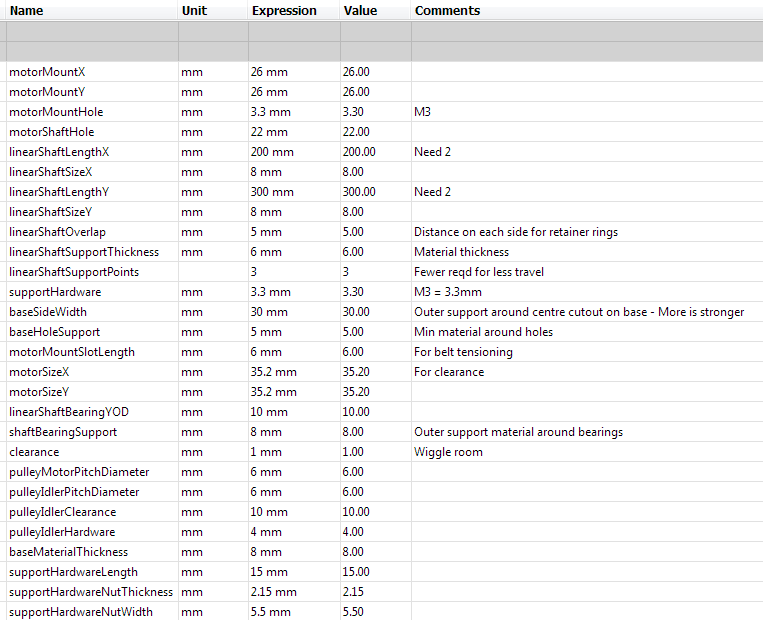

Here are all of the variables required to make a CoreXY table:

(I have not finished the X axis yet, expect that to grow slightly)

The advantage of this system is that I can find old components around VHS, my storage locker, the Hackery, etc, and punch their dimensions into Fusion 360’s parametric solver. It will then magically reconfigure the platform for me. Like if I had shorter precision rod, for example.

Likewise if I had larger motors. It’s a little bit difficult right now, because Fusion 360 only keeps track of parameters local to models, so I have to copy changes to each one when the values get changed.

That’s made easier by using an Add-In called ParameterIO. It doesn’t work out of the box, there is a bug because of the dimensionless quantities in linear patterns.

I had to edit line 219 of:

C:\Users\Jarrett\AppData\Roaming\Autodesk\ApplicationPlugins\ParameterIO.bundle\ContentsParameterIO.py

To say this:

unit = ' '

try:

unit = _param.unit

except:

unit = 'FUCK'

result = result + _param.name + "," + unit + "," + _param.expression + "," + _param.comment + "\n"

```

(The swears weren't necessary for correct operation, but they sure made me feel better)

To import, the same problem exists, but it was easier to just delete the model parameters in the CSV file, because they're unique to each model and don't carry over.

There are a couple more issues with the assembly, mostly down to my inexperience with Fusion 360. I don't know how to mate surfaces together, for example. I also intend to add in a laserKerf variable that will widen or narrow edges appropriately. And a couple measurements that can be tightened up a little to save some space. Nothing insurmountable. I'll fix all that in, like, half an hour when I come back to this.

Cloud stuff confuses and frightens me, but I think this a link to the file:

http://a360.co/20lCWgG

Stuff will be tweaked, fixed, and added to over time.