I needed to make an odd sized copper pot for my brewing operations, it’s a double boiler actually. So after finding out the cost to purchase copper filler rod for my TIG ($$$), I elected to make the vessel from sheet copper and assemble it with stainless rivets.

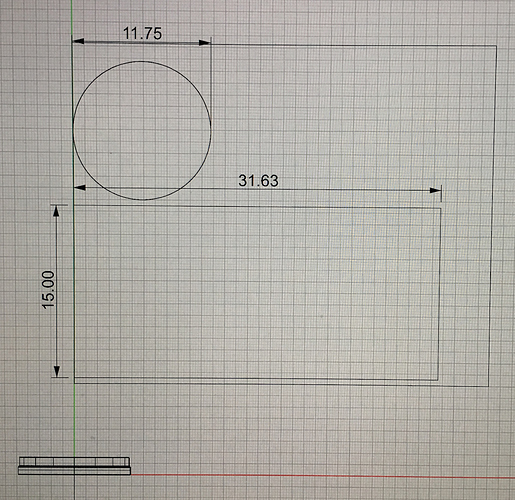

I started with a cad model to determine the size of rectangle to cut to make the side from based on the diameter of the bottom plate. I then CNC milled up two form discs, one with a 1/8 radius to allow the copper to bend smoothly around the 90 degree edge. I was amazed at how forgiving the copper was, I am used to dealing with aluminum mostly, which is not so forgiving.

Since the bottom turned out so well I decided that constructing a full length form for the side assembly was not necessary but after struggling to tightly cinch the side to the radius of the bottom pan I wish I had. It still worked out but that was likely due to some seriously good luck. Unfortunately the side is under a little pressure and would spring back if the rivets were removed so it’s less than ideal but will get the job done.

I am currently working my way up the seam to the top, in the last photo you can see my temporary fasteners called clecos poking through. Those are under some tension which isn’t ideal but the vessel is a cylinder now! I will need to stop short of the top and go back down to put a second row of fasteners along the inner edge of the seam before doing the last procedure.

The last procedure is going to be a little bit more tricky. I need to put a slightly more than 90 degree bend to form a flange at the top which will mate to my current boiler lid, which is domed. The flange will splay outwards so some serious forming and stretching will be in order. I plan to make a form to capture the outside top edge at the bend line as well as an inner plug to prevent the side from deforming. I really hope that the flange doesn’t crack when I do this because you will see a grown man cry if it does…

I do have a contingency plan if it does but that involves milling some thicker copper plate up to form a flange and I don’t want to do that because so much more work and $$$.

The last steps will be to apply some heat to the seams and seal them with lead free solder and then attach the vessel to the boiler lid. Total cost to make a 9.75 inch diameter by 14 inch deep vessel is $140, and there is enough copper left over to make a few things with (about 1.5 sq feet) I started with a sheet of 0.032" thick at 36 inches by 29 inches.