I spent over 3 hours today fixing the Prusa i3 clone and gantry printers.

Some things to note…

The gantry has a built in leveling sequence, first to a “prepare” then “pre-heat PLA”, then “prepare” and “Manual Bed Levelling” You will need to go around 3 or 4 times to get it right.

The prusa clone - front-left of the bed, use prontoface on the laptop and home the Z, use the small nylon nut to get the height right, then move to the other 3 points on the bed using the hex driver.

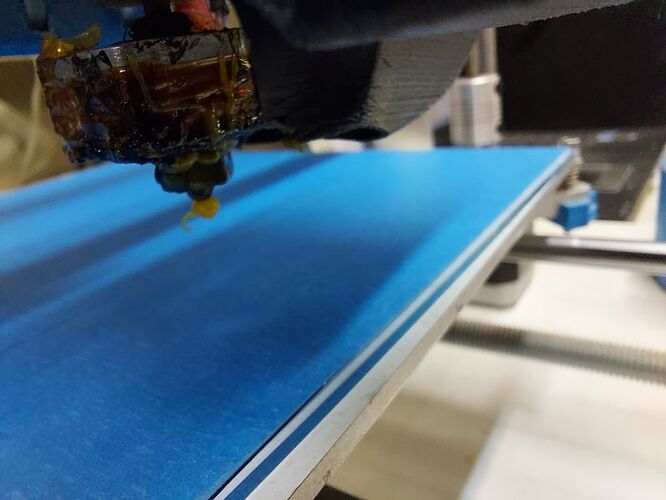

When putting on new blue tape - butt the pieces together and don’t overlap the tape. When leveling the bed you are trying to get a paper thickness (same as blue tape) between the nozzle tip and bed, so if you overlap the tape the gap is going to be wrong where the tape meets. Also do not wrap the tape under the glass. This is wrong:

Do not leave a blob of filament on the nozzle for the next person to clean off.

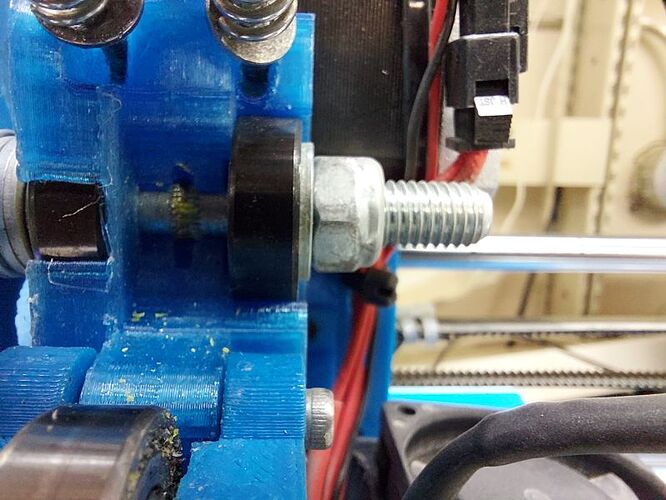

This is also wrong:

Every so often and especially if you jab filament in the nozzle you will need to clean the teeth in the hobbed bolt. This can be done by flipping the idler down and using the points of fine tweezers to remove stuck filament:

Filament stuck in the teeth like this is bad and stops the flow of filament.

The Prusa clone is printing well, the gantry is printing OK but when I reassembled the nozzle to remove the jammed filament I didn’t get it quite right and I will re-do it in the near future.

But it is useable.