Post Mortem Time:

First: Big thanks to @Lukeo for his help with preparing and running the workshop!

12 Attendees. 5 existing VHS members, 7 non-members (some of whom expressed plans on joining). One attendee had prior experience with leatherworking.

How the non-members found out about the workshop:

- stumbled across it on vanhack.ca

- referral by an existing member/other participant

The workshop had sold out fairly quickly, so I didn’t do a lot of advertising it in public. 12 people was a good number - enough space around both the craft table and the work tables.

Total time was about 5 hours, and all participants who stayed were able to finish completely (I had expected some to take them home to finish, one participant left early and did so).

Before the workshop @Lukeo and I had pre-cut all the leather - This worked well, with a single kit having some delicate thin edges (must have bent up in the cutter) - Something to double check next time.

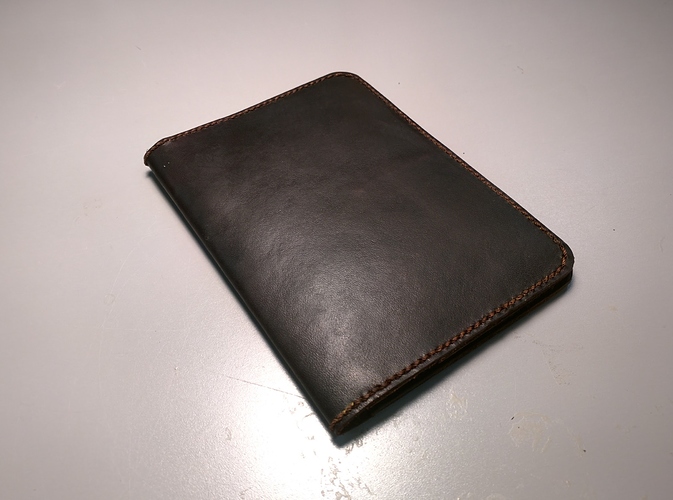

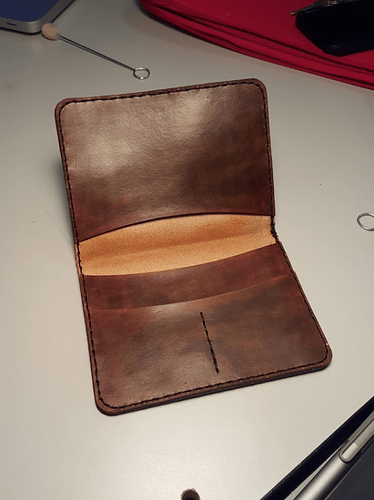

The schedule (dye the leather , while dye dries I presented on designing the patterns to cut, treat the dyed leather, Coffee break while it dries, Learn about saddle stitching, assemble) worked well. Strongly encourage putting a break in the middle of 5 hour workshops.

The TV/chromecast worked okay for showing the designing. Arranging for someone with a more powerful laptop with VGA or an HDMI projector for the space would be a plus.

Lots of interest in etching the projects - still iffy on the logistics of pulling this off, but might experiment with including it next time.

Supplies Notes:

- Amount of leather was correct, came in a bit under cost estimate.

- Needles were over cost estimate

- Treating supplies (mink oil/ mink oil paste/ saddle soap) was sufficient - we had left overs of all three, probably enough paste/ saddle soap for next time, need more oil.

- Only needed one wool dauber/participant, should have just had a few spares for dropped/etc.

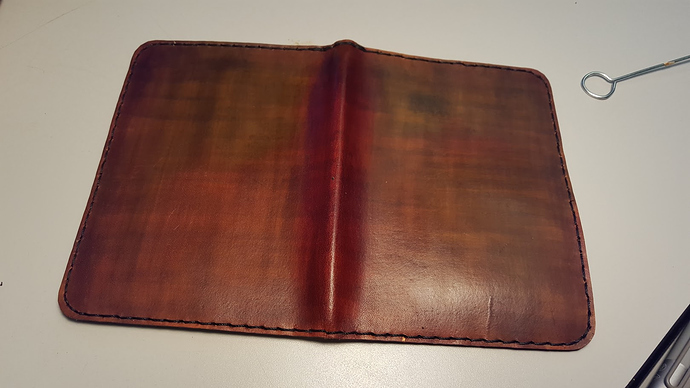

- More dye. We used two small jars, and used it all up. One pot / 4 people would probably be more appropriate. More color variation for dyes - dark and light brown were very similar.

- More thread. Cut it close on this one by overestimating how much was on each spool. Should have bought a larger bulk roll.

- bottlenecked a bit on the single lighter in the space - forgot to check how many we had. Should try heat gun to see if it will work as an alternative.

In total, the supplies costs were approximately what I had estimated when pricing the workshop.

Need to remember to warn that oiling middle crease will soak through and change outer colour.

Participants were positive on the experience, and it was fun to run.

Anyone with additional feedback, feel free to post/ drop me a line.