Today I calibrated the X and Y axes by doing a series of 4 holes spaced 12" apart, measuring, adjusting the “steps per”, rerunning, etc. They’re now pretty well calibrated.

But now I’m limited by the rigidity of the machine. I tried to cut through a 1.25" piece of pine lumber, but after about 0.25" the machine vibrated too much, the endmill caught a sidewall and jerked a few steps. I stopped it quickly.

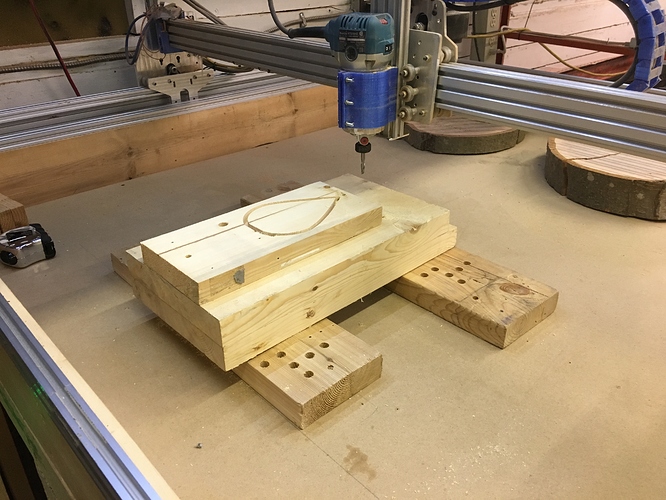

To solve that, I raised the workpiece up so that the Z axis of the machine is at the top of its travel. I recommend we lower the machine back down to how it was at Cook St. There’s not enough rigidity for this machine to work well when the Z axis is extended down past 2 or 3 inches, so we might as well lower the whole machine back down to how it originally was, reducing the work envelope so that we don’t have to build up our work holding so much.

With the workpiece up high, and the Z axis almost fully retracted, I was able to cut a bit deeper than 0.5" into the pine before the machine started vibrating so much that the endmill caught an edge again.

Next time I will try go even slower (but this was already really slow).