I use a lot of hardware debugging tools. These tools, in the process of debugging my sketchy hacky bare circuit boards, also look like sketchy hacky bare circuit boards. I consider that a “project”, not a “tool”, so an enclosure is warranted for a tool I intend to use a lot. In line with those goals, I designed a Bus Pirate case a few years ago, but I’m kinda bored of lasercut acrylic.

I have a new debug tool, an FT232H breakout. It can talk a lot of protocols, and Python scripting looks pretty good.

So let’s find a good chunk of walnut in the scrap pile donated by @Hekseskudd

Very rough planning:

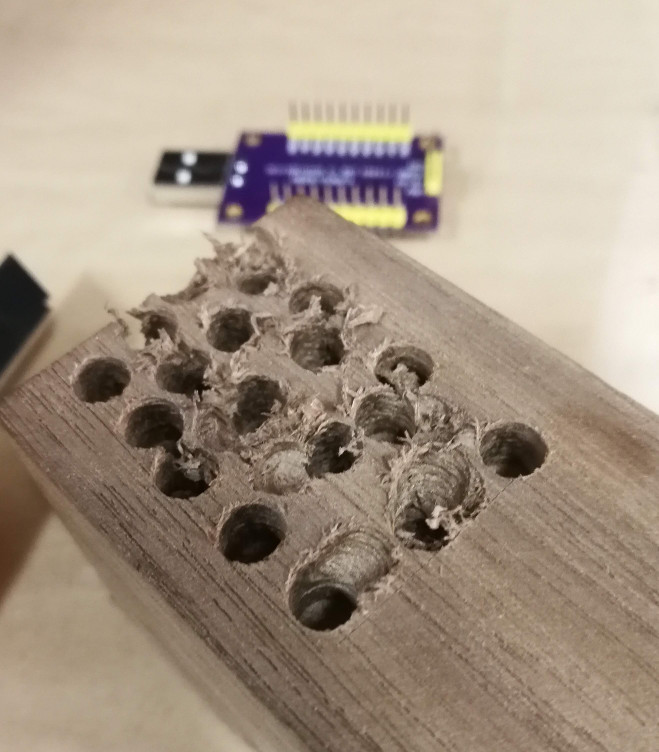

After marking out the outlines of the board, I set a depth stop on the drill press and roughly took out the bulk of material.

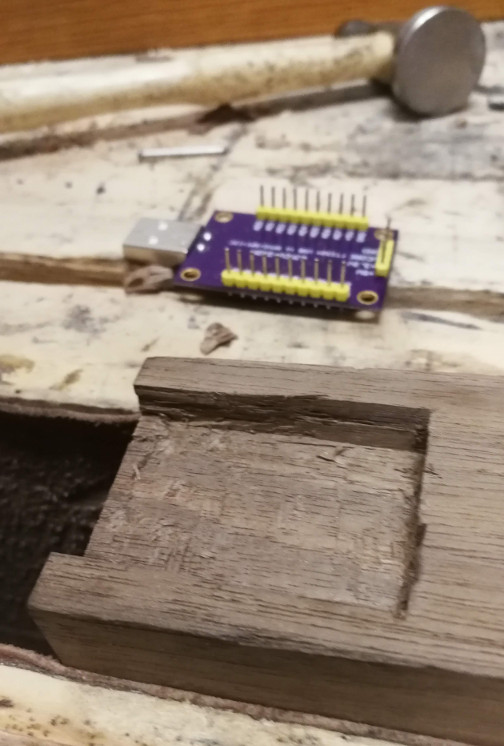

Thanks to @jon (different Jon), VHS has some awesome wood chisels, and I was pretty stoked to find them still sharp, probably thanks to @mike.

Walnut is super nice to work with, and I’m sure my next one will be neater. It’s been about fifteen years since I did any serious wood carving, so it’ll take a bit to get back into the swing of things.

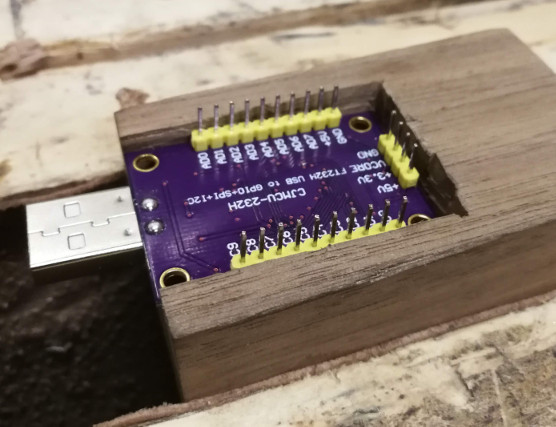

It fits, though.

The next vertical level involves a little bit more shark jumping. You can see that one of the standoffs chipped off, and general work is messy. Three mounting points is fine, and dimensionality is okay, so press on. The real problem is that I didn’t go back to the drill press to get to the lower level - That would have been faster, cleaner, and saved all of my standoffs. Oh well. Don’t be lazy next time ![]()

In parallel with this, I drilled out a variety of hole sizes to see what would best accept an M3 threaded brass insert (actually designed for plastic, but I’m a rebel).

Near hole too small, rear hole juuust right. It’s a 5/32" drill bit.

Then, back on the main piece, I chopped it down to size, and started shaping it with a mixture of handplaning and sandpaper.

And a quick coat of walnut lacquer.

Done! I’m satisfied. This whole process only took about three hours (spread out over two days when I had some spare time).

I’ll probably do something similar for a bunch of my stuff, I’ve been intending to use some of these scraps for over a year now. And it’s not hard for anyone to get into! Just take care of the chisels and the handplanes, they’re awesome. Certainly more zen than turning to one of our CNC tools immediately (although those are fun too).