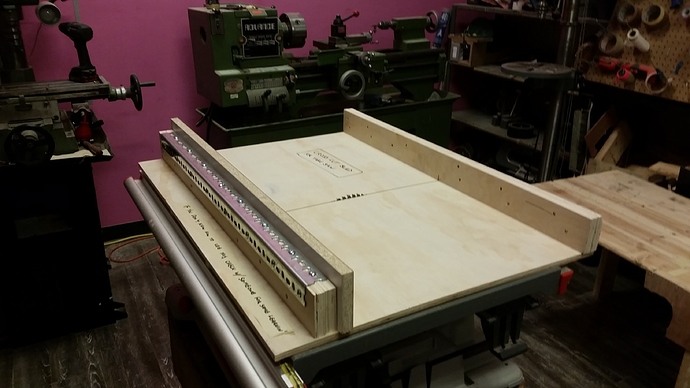

I built a crosscut sled for the table saw, so we can make accurate cuts that the miter guide can’t do. I’m also thinking about making a box joint jig. Is there interest in getting a Dado set?

Make sure you label them!

Might be a good idea to draw installation/assembly instructions on them too.

This is awesome!

Maybe we can laser etch a ‘let me google that for you’ url into the thing.

Sorry, I didn’t mean to point out that you were doing it wrong.

Good job though.

Awesome. Thanks Stu for doing this.

What’s the protocol for using the table saw? Do we just take it to the loading bay, then clean up after? Are there any hours (aside from the obvious late night/early morning that we should avoid)?

It can be used in the workshop as long as the noise isn’t significantly disturbing other people using the space. If there are a lot of people doing stuff, or there’s a workshop or something going on, take it to the loading bay. Does this fall into the ‘be excellent to each other’ category?

Also, please avoid spraying saw dust onto the lathe or other metal working

tools; it is harmful to the equipment.

For a dado blade we probably need dust extraction, they generate a ton of material (which is why they’re so handy).

I just ordered a new filter for the shop vac so it actually retains sawdust. The table saw has a vacuum port. Will this be sufficient?

Hard to say. Is worth trying, you’ll be emptying it a lot but that won’t hurt. Dado blades need a lot of power in the saw too, you might find that saw can’t do it (or that you have to make multiple passes (which sucks for accuracy).