Thanks!

things we will need to acquire in order to sustain this long term:

- barrels and barrels of IPA

- butt load of gloves

micro fibre cloth[EDIT] PEC sheets- novus 1 plastic cleaner

- fresh resin that’s not 4 years past exipiry date

I would like to donate towards sustaining the formlabs printer long term.

Please put me down for $100

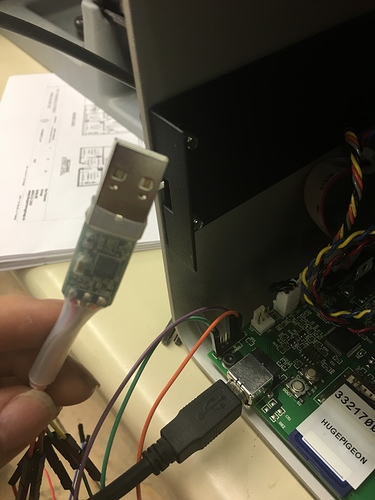

it took some trial and error, I ended up updated the firmware on the Form 1 to 1.44 OpenFL version.

the unit now works with (maybe exclusively) the “hackable” OpenFL version of Preform slicer.

more info here:

We can get some silicone spatula’s for cleaning out the resin. Dollar store

The cheapest place I know of for 99% alcohol is costco. 4 bottles for $10. Anyone know of a cheaper place? I would love to hear

Couple of these bottles would be nice for the alcohol needs a cap though.

www.amazon.com/Economy-Bottle-Squeeze-Medical-Tattoo/dp/B00WTHLR2M

They are $2 each at Yoko dollar store.

Those trays are made of acrylic so we might be able to find orange acrylic make some of our own trays. Or just some lids for the clear ones we have.

I use Z Vat and store my full trays in a drawer with the lid on.

This is one of the important videos I was looking for. starts at the 6min to talk about important safety issues. The first part is a good introduction to SLA’s

which video?

the donation came with squeeze bottle and the “official” metal spatula.

more squeeze bottle may be useful.

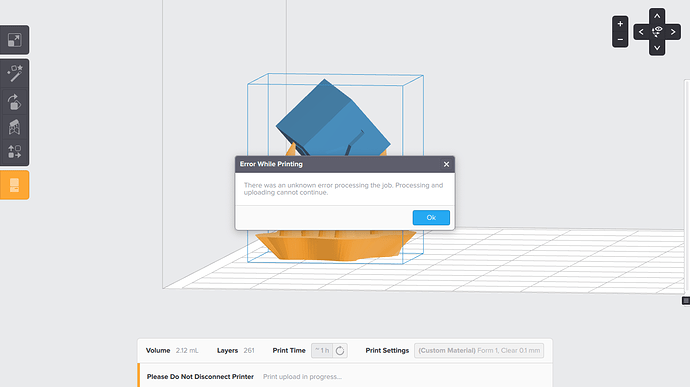

i’ve been struggling to get the custom material option to work.

I detailed it on formlab’s community forum:

I also opened a support ticket for it

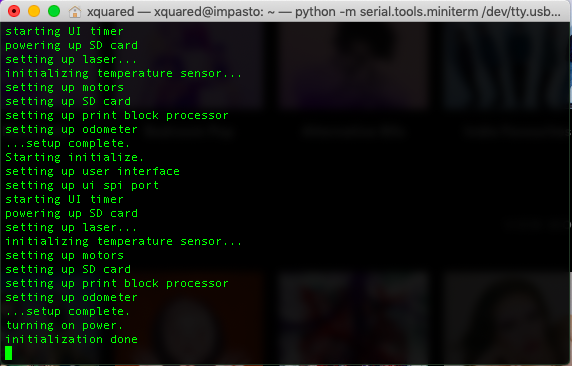

Brief update on progress from @RolandClarke and @xquared last night.

Spool3d Fun To Do - F1+ Blend arrived ($114 for 1 litre!) for testing since the likely cause of recent failures was the expired resin in the donation box.

3 tests - while I was there, some after I left at around 8pm.

- flexible armor - some detail but may not have printed layers correctly

- Star Trek logo - results look very promising, detail looked very good and X-Y dimensions were spot on. Unfortunately, the Z axis seemed to be compressed. Design thickness was 4.66mm and print dimensions were 3mm.

@xquared who has done all the research thought that the Z axis settings needed adjusting, and that on initial print that the top assembly might have been pressing too hard into the print tray and squashing the print (as I understand, please correct me if this is not right, @xquared)

Third attempt - in the print software, there was a setting for Z-height offset. the maximum setting for this was 1mm, so this is where we tried it (even though the offset actually looked like it needed 1.66mm)

- Star Trek Logo - Z height now 4mm !! which is great since the Z-height settings added a full 1mm to the print height. At this point it is likely that something inside the machine needs to be fiddled with in order to restore the Z height settings to back within their normal range. after this more detailed calibration can hopefully take place.

SUPER FUN. Looks like a 90% working resin printer now sits at the hackspace!

made a page over on the wiki:

http://vanhack.ca/doku.php?id=tool:form1sla

will be working on it on and off, feel free to discuss and contribute

just to update all interested party that i am waiting on an order of pec pad to show up so i can clean the mirror

Awesomeness. Looking forward to seeing that clean out process. I’m curious about how that laser is rigged up inside.

We’ve run a couple of test prints so far today. The first one was printed on supports and angled, but the supports all fused together and the bottom of the cube was elongated and distorted:

Printing straight to the print bed gave us more of an expected result. The first half of our 10mm cube was compressed, but things got much better above that line. According to Got the Printer today, and some questions - #4 by Zachary_Brackin - Form 2 - Formlabs Community Forum, that is as expected:

Really great to see people working on that resin printer. How are supplies? Let us know if you need cash to buy resin/cleaner etc.

found someone else with almost the exact problem. everyone on that forum is stumped as well. The only thing similar in OP’s and our cases is that we are both using non-formlab resin.

the most enlightening info comes from an formlab employee:

most places are sold out of funtodo gray resin, but we might be able to still get Black